Sonntag, 22. Juni 2014

Marbled Beer Soap

I wrote a guest post last year for Soap Queen with a tutorial for marbled beer soap and I recently discovered that I had no post on SkinChakra blog. The guest post was prepared with Zoigl beer, which is basically a regional beer known to Oberpfalz (the region I live in). This one is prepared with wheat beer (Weissbier) which is a kind of light beer. I made some minor changes to the original recipe but the base is the same.

Basically, the lye is prepared with beer instead of water. In order to get the marbled optic you have to prepare two different lyes, one with water and one with beer and then mix them as you wish by pouring the soap into the molds.

I simmer the beer a day in advance to evaporate the main part of the alcohol (heat the beer in a water bath and not directly). Then cool it down and filter it before adding the NaOH. You can even freeze the beer but it works without it perfectly. Our Bavarian beers are 500 ml, you'll probably have 250 or 300 ml beer bottles. I simmer 500 ml beer to ca. 200 ml. The amount and the kind of beer you apply defines the final color of the soap. It's up to you which beer you choose and which concentration you apply. For your first trials you can even prepare a simple beer soap with only one lye solution and replace the whole water with beer. In that case, you'll have a uniform color and no marbled optic.

Since the soap is basically purchased and used for men and by men, I apply Cedarwood essential oil which is a very skin friendly essential oil as a fragrance. This suits the optic and the concept of the soap perfectly. Our cedarwood essential oil causes no accelerating on the trace and you have enough time to play with the soap.

Before we start I want to recommend you to read our older posts and general information regarding hygienic manufacturing practice in cosmetic lab, introduction to Basic equipment and utensil for a cosmetic lab and the safe handling of Sodium hydroxide.

I've calculated 7% superfat for this soap but mix all of the oils from the very beginning. For simplicity I divide the fats into 2 equal parts here, but you can change the relationship to 1:3 or 1:4 as you wish. It means I prepare half of the lye with water, half with beer and then divide the fats and oils into two (eyeballing is enough).

Here is what you need for the soap (1000 gr oil)

for the beer lye:

190 gr cold beer (simmer the beer at least one day in advance)

69,10 gr NaOH

For the water lye

190 gr cold distilled water

69,10 gr NaOH

and here is your oil mixture (which you're going to divide after your fats are melted and all oils and fats are mixed)

20,0% Palm kernel oil (200,0 gr)

20,0% Rapeseed oil (200,0 gr)

20,0% Sunflower oil (200,0 gr)

15,0% Palm oil (150,0 gr)

10,0% Coconut oil (100,0 gr)

5,0% Babassu oil (50,0 gr)

5,0 % Castor oil (50,0 gr)

5,0% Camelina seed oil (50,0 gr)

2,5% Cedarwood essential oil (25,0 gr)

Further you'll need:

Silicone or wooden loaf molds (you can try our mini silicone molds for trial batches)

(optional) disposable pipettes

a water bath

A Thermometer

an stainless steel pot or Pyrex jar (to heat the oil in the water bath)

A stick blender (try to find some with plastic stab)

a Glass beaker (for the essential oil)

A plastic beaker or bowl for NaOH

2 plastic jars for lye

Plastic or silicone spatulas or spoons

A sprayer bottle with alcohol

Safety goggles, gloves and mask

Here we go:

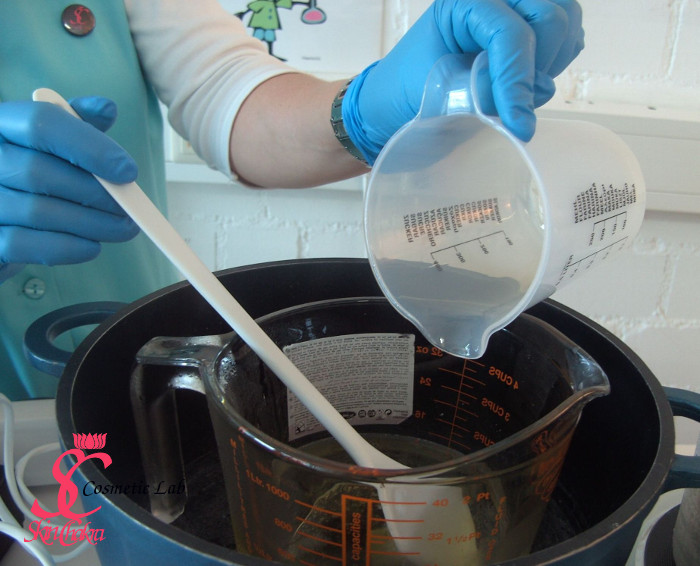

One: Separately prepare the water and the beer lye. Weight carefully (carrying your safety gloves, mask and goggles) Sodium hydroxide in two plastic beakers (one for the beer lye and one for the water lye). Weight in two other plastic pitchers or beakers the cooled beer and distilled water.

During summer or if you're living in a hot area put the water (beer) pitchers in a cold water bath for a better temperature control.

In a well ventilated room carefully and slowly add sodium hydroxide to water and beer separately and under stirring. Do not inhale the vapors directly. Be very careful. Keep the water baths on a counter safe from children and pets and wait until the temperature reaches around 35-40 degrees Celsius.

Immediately after addition of NaOH to beer, it turns to an ugly cloudy brown with a disgusting smell. Don't worry it turns to a beautiful beer soap later.

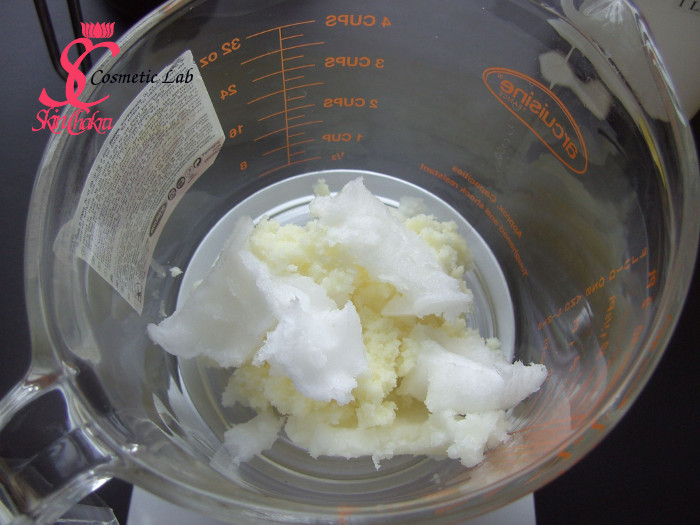

Two: As you're waiting for lye temperature to reduce weight your solid fats (palm oil, palm kernel oil, babassu oil, coconut oil) in a water bath. Do not overheat the fats. A temperature of 50 degrees Celsius (for the water) is quite enough.

Three: When the fats are melted, turn the water bath off and add the liquid oils and mix.

Four: as lye and oil mixture have a temperature around 35-45 degrees with max. 10 degrees difference divide the oil into two parts (eyeballing in enough).

First start with the water lye. (If you have a soap buddy and have two stick blenders you can run this part simultaneously with the beer lye)

Tap your stick blender a couple of times at the bottom of the oil pot to get rid of large air bubbles. Very slowly and with the blender not yet on add the lye solution over the stick blender to the oil mixture. Stir a few seconds manually and with the blender not yet on. After a few seconds turn the blender on and stir in short intervals.

Do the same with the beer lye.

With patience, the batter comes to a relatively thick trace but it takes time. If you don't have the patience or the batter doesn't come to a thick trace, don't worry. The thicker the batter the better the marbled optic but with very low viscosity trace you'll still get a marbled effect.

Five: After both batters come to your desired trace, slowly and under stirring divide and add the essential oil (eyeballing is enough).

Six: The fun part begins.

Layer by layer add alternatively the beer batter and the water batter into the mold. We apply both soaps from the middle of the mold. The higher you hold your hand by pouring, the more the layers blend. It's totally up to you how to design the soap. Each time is a single experience with a nice surprise.

Seven: For the upper part of the mold we blend the batters a little bit more till they reach a caramel-like consistency and pour them (scoop them) alternatively to the mold.

Eight: Spray the surface with spray alcohol to avoid soda ash over the soap surface. Wrap the soap in towels and let it rest for at least 48 hrs before demolding.

Nine: Demold the soap and cut it as you wish. here we have some conventional bars and a cute beer keg cut with a cookie cutter.

Let the soap rest on the racks for at least 8 weeks before you wrap it or bring it over your shelves.

You can buy all the ingredients for this project in SkinChakra® Online Shop.

BeHappy and have fun.

SC PaperDesign am : http://sc-paperdesign.com/archives/70-unknown.html