Montag, 6. Juli 2015

Emulsion stability

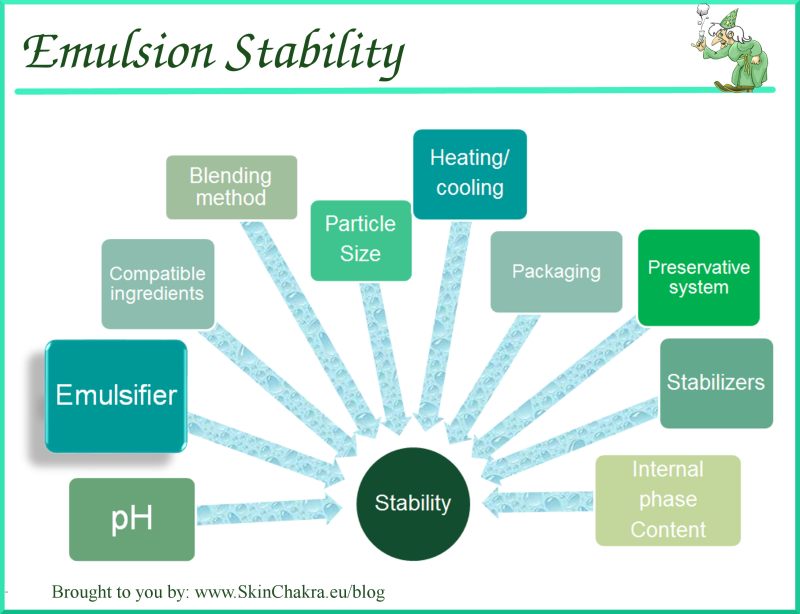

There are numerous factors which can affect the texture, skin feel, appearance and the stability of an emulsion. The more complex the formulation, the more the factors that can affect the stability of teh emulsion.

This is why I always advise the students to start with KISS principle and prepare simple emulsions as they start working with a certain ingredient (specially an emulsifier). Of course there is no fun in making a boring emulsion, containing just one oil, plain water, an emulsifier, a stabilizer (perhaps) and a preservative (of course). All of us want to make exciting emulsions with several exotic oils, hydrolats, plant extracts, active ingredients and as much ingredients as possible. But suppose you prepare such an emulsion and you're at the end not satisfied with teh texture or the skin feel, or even worse. Your emulsion is not stable and breaks in two or more phases. How are you going to find out which ingredient/factor has caused the destabilization? What about all those precious and expensive ingredients that are now useless?

Try it the other way. Start from very simple (I mean really silly simple) emulsions and build the emulsion from the base upward. In that case, you'll know your system fundamentally and would know (almost) all factors that might affect its feautures and functions.

Coming back to our stability talk, let's review some of the most significant factors that might affect the emulsion stability:

Emulsifier is of course the most significant factor. (Have you read my other post about emulsifier choice?)

It's not just about an O/W or a W/O , it's far beyond that. Some emulsifiers are suitable for sprayable emulsions with low oil phase concentration, some on the other hand would work in emulsions with high oil concentrations, some do not work well with esters and some have no alcohol or electrolyte tolerance. Chosing the right emulsifier for the right purpose would spare you headache & frustration.

Internal phase content is the percentage of the water phase in a W/O emulsion and the percentatge of the oil phase in an O/W system. As mentioned above, it depends basically on your emulsifying system how much water or oil it can emulsify. By deviating from the optimum capacity of the emulsifier, you may dedstabilize the system. Sometimes you can compensate this destabilization by appliying stabilisers.

Stabilizers are not always necessary but in some systems very helpful or even necessary. they usually stabilize the system by modifying the viscosity and flow properties of the system. Depending on the system your stabilizers might be water soluble (such as hydrocolloids) or lipophilic (such as fatty alcohols and wayes). The right choice could be as important as the emulsifier itself.

Heating & cooling process (for hot process emulsions) is another important factor in emulsion properties and stability. I don't know where the origin of this myth in the DIY society is, but it is very common that people talk about "heat and hold" as they descrie their emulsion making. I assume that the original CREATOR of this concept has used it for a certain application in a certain concept and then, unfortunately as we daily observe in case of INTERNET SCIENCE, others have obediently followed her without knowing that this instruction was for a certain group of ingredients. In any case I can not understand the sense of heating ingredients (specially as we're talking about "natural cosmetics", applying heat sensitive ingredients) to some 80 degrees, holding them for 20 minutes by that temperature and then blending the water and oil phase.

The process of heating the ingredients and cooling the emulsion can affect the texture, viscosity and the stability of any emulsion. If you want a reproducible process , keep record of your procedure.

Particle size is another important factor in emulsion stability. All emulsions are thermodynamically metastable systems, meaning they're going to separate sooner or (better) later. It's totally enough for you if your emulsion remains stable during the predetermined shelf-life and slightly more but you can not expect an emulsion to remain stable for an eternity. For many "natural cosmetics" and simply because of the limited shelf life off the plant oils applied in the emulsions, the shelf life is shorter than the usual 5 years for conventional cosmetics but still you don't expect your emulsion to be stable for only 3 months. The smaller and the more uniform the particle in an emulsion, the more stable the emulsion. This is partly achieved by applying the right heating and cooling procedure as well as the blending method. Certainly you can prepare a 50 ml stable emulsion by blending with a milk frotter or even a simple glass rod or a spatula but that wouldn't be possible for higher volumes. The larger the dispersed particles in an emulsion, the higher the chance of their collision and STICKING together which at the end leads to emulsion destabilization.

This leads to blending method to be another important factor in emulsion stability simply because blending method will affect the particle size.

Ingredients compatibility: Some ingredients simply don't match together and applying them in the same emulsion can cause destabilization. This is most significant for ionic compounds but can be valid for other ingredients as well. One example is, as mentioned before alcohol or electrolyte tolerance of your emulsifier. Or electrolyte tolerance of your stabilizers. This should be regarded as you choose your ingredient for each formulation.

pH is another fundamental factor soecially with modern, new "natural" preservatives. Most cosmetic ingredients have an optimum pH range. Going to a lower of higher pH than their optimum performance pH can both affect the stability as well as the performance. Suppose you have a preservative system with the best efficacy @ pH around 4,5-5,5 and a gum with the best performance @ pH between 3-5 and an emulsifier system with the best performance @ pH between 5,5-7. It is clear that all these ingredients could not be gathered in a certain formulation. Deviation from pH can not only inactivate your ingredients, it can destabilize your emulsion.

An effective preservative system is a necessity both from a legislative point of view and from a marketing/consumer care point of view. This is a nightmare to any formulator and manufacturer to sell an unpreserved or not-sufficiently preserved product. Most modern preservative systems, as mentioned above have an optimum efficacy pH-range. Deviating from this pH can not only affect the microbiological intergrity of the product, it can even affect the stability of the emulsion.

Packaging systems are the least exciting factors to a formulator, however they have a major impact in product integrity and stability. The packaging shall protect the product, inhibit any interaction between the product and the environment (loss of water and volatile matter, absorbtion of water from the environment) and shall be inert to the product itself, meaning no interaction with the product. A suitable packaging and dispensing system is not important from marketing and sales point of view, it is vital to the integrity and stability of the product.

Hope considering these factors will help you improve the stability of your emulsions.

Thanks for your visit.

BeHappy and have fun