In part I of this study we reviewed blends of xanthan gum and LBG. You can refer to that post to know more about the background of this study and more about the chemistry of xanthan gum.

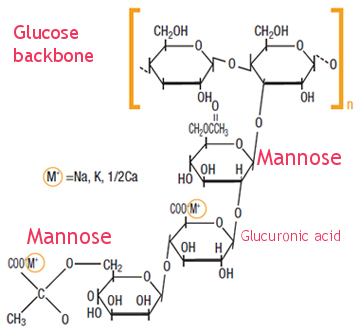

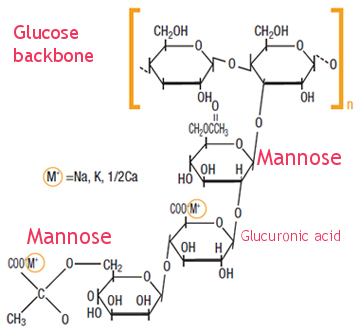

Xanthan gum is is a broad spectrum gum in food, cosmetic, pharmaceutical and many other industries. Its dispersions in water could be quite transparent (depending on the particle size) and are stable over a broad pH range (1-13). Although xanthan dispersions make high viscosity solutions, they are no gels from a "physicochemical" point of view. Xanthan is a clucomannose polysaccharide.

Photo: Cargill

Konjak gum is extracted from the tuber of "amorphallus konjak" an edible medicinal plant native of tropical and subtropical Asia. Konjak gum is a polysaccharide consisting of glucose and mannose units (glucomannose) with a mannose:glucose ratio of 1.6:1.

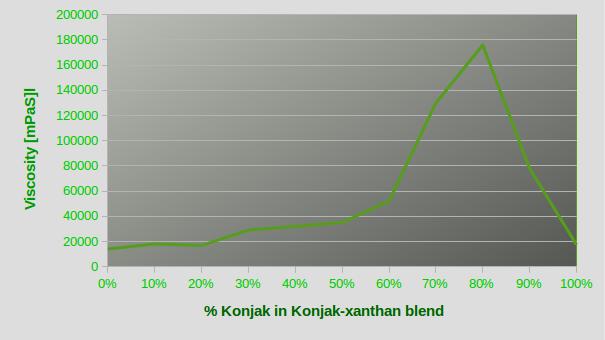

Konjak gum has outstanding properties. It swells in water even at cold temperatures but complete dissolution occurs at 90 degrees. Konjak solutions are stable in a pH range between 4-10. Konjak alone makes a very nice gel in water but in kombination with xanthan, it creates amazing gels with higher viscosities than any of xanthan or konjak solutions alone.

I really like konjak-xanthan combinations and apply the combination very often in my emulsions. Depending on the emulsion, you can preblend the mixture in a part of the oil, in glycerine or simply sprinkle the blend slowly to the emulsion under stirring.

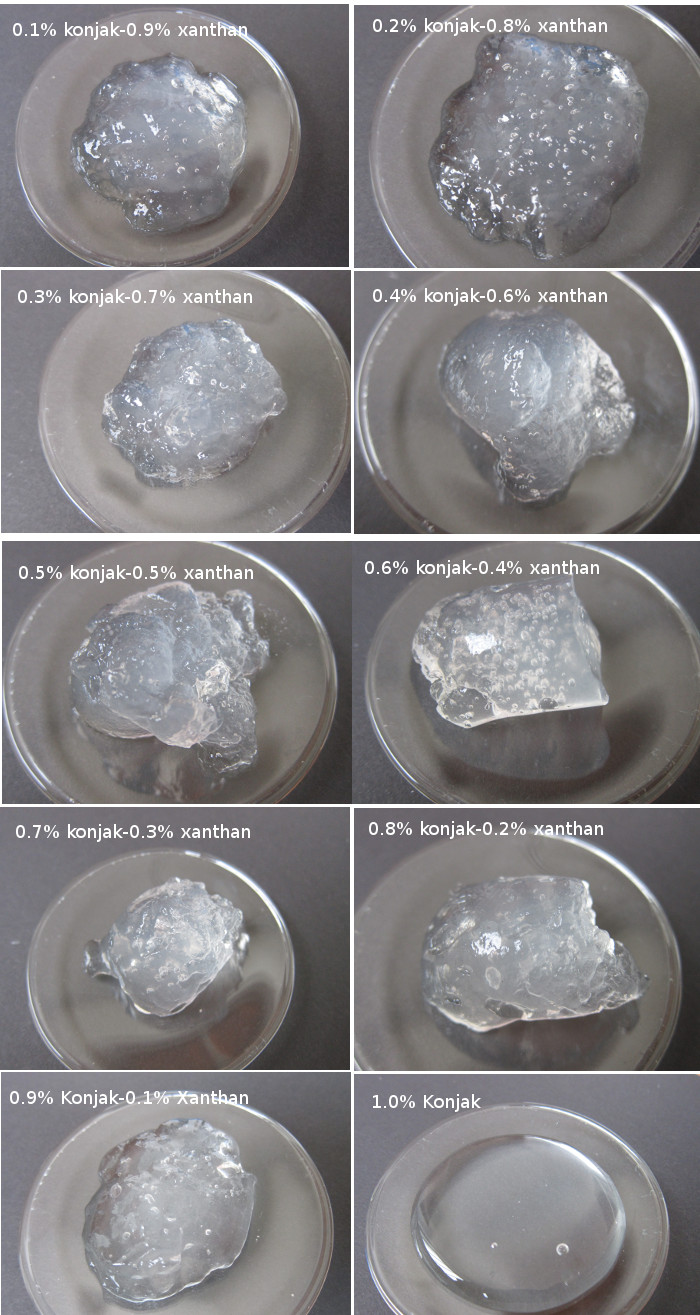

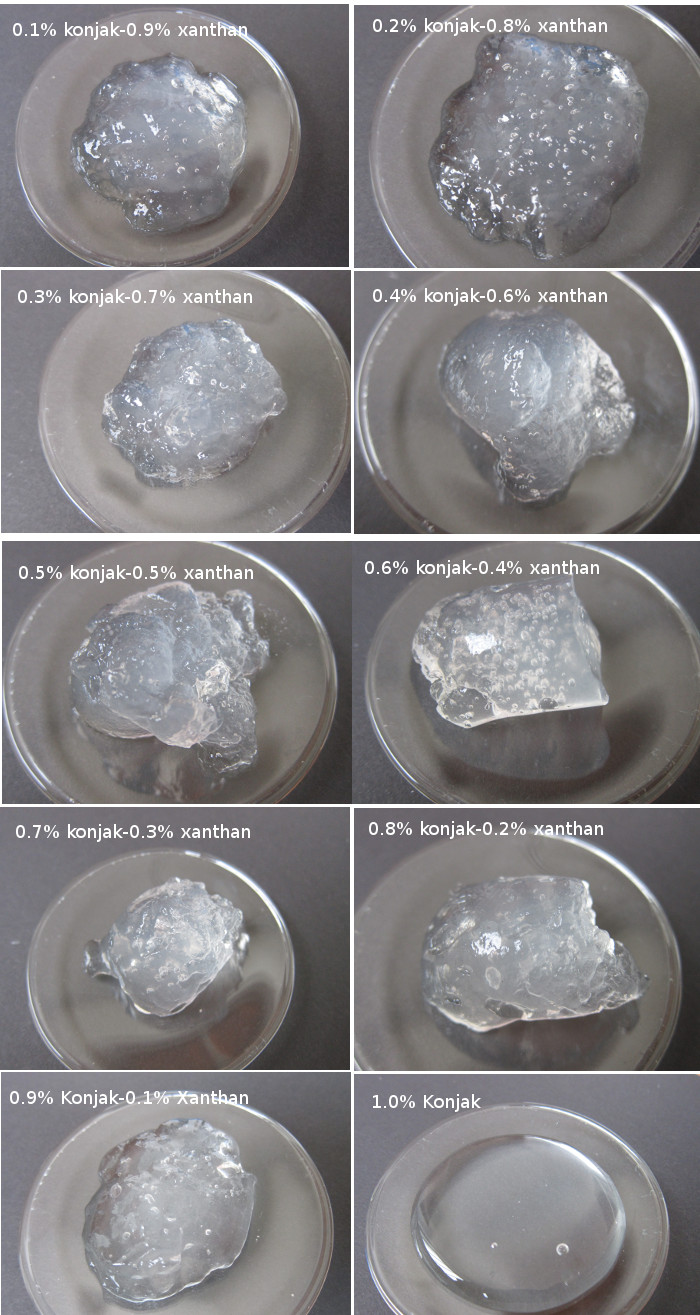

Konjak solutions have a poor transparency, xanthan however (depending on the particle size) makes transparent solutions. By gradual increasing of the konjak concentration in the blend, transparency becomes poorer. In this photo you can have a visual judgement of the viscosity and the transparency of the blens.

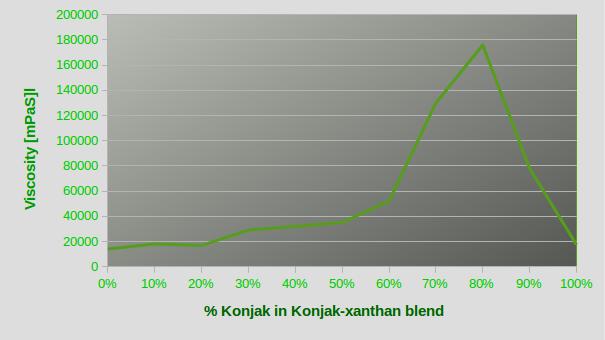

For this experiment, we've blended xanthan and konjak in a 1% total concentration with varying ratio of xanthan:konjak. The highest viscosity is achieved by a konjak:xanthan ratio of 8:2. This means by adding just little amounts of xanthan to a konjak solution, you can create high viscosity gels or stable cream gels.

We've directly dispersed the gum blend into cold water under high shear, then heated the blend in a water bath for a few minutes. After cooling down, the pH was adjusted between 5-5,5 and the mixture was preserved with 1% Euxyl® K903.

Here is the result of our experiment:

I hope you'll enjoy applying xanthan-konjak blend in your emulsions. Don't hesitate to send me your questions and comments.

BeHappy and have fun