Glass vs. plastic

This is a never ending debate in cosmetic manufacturing.

Obviously most of you detest and reject plastic. Before you make any decision for you packaging material however, there are several aspects which should be thoroughly considered.

I have met many artisan manufacturers who have originally decided to exclusively use glass and have eagerly paid the higher prices for glass vs. plastic but after a while changed to plastic because of the higher shipment costs, higher material costs and most importantly because their customers didn't want to have any broken glass in the bathroom.

It is your legitimate preference to go either for glass or plastic but before making your decision please consider all aspects.

Anyway, this specific post however is not about glass or plastic for your final products, it is about the material you may want to use for your stability tests.

Those of you who have participated in the Certificate in Cosmetic Stability Testing, have watched the webinar and participated in the Q&A have asked me which material to use for your stability tests.

I Can not give you any concrete answer which one to chose. The choice depends on your budget, on the availability of each material in your region, how you can source and handle each material. This is something you have to consider yourself and probably come to a conclusion after some trials.

I have to mention however two important facts:

- You need at least one complete test with the final marketing packaging

- It doesn't make any big sense when you sell your product in plastic and run the stability tests in glass or vice versa

Glass is usually the most inert material (compared to plastic). It wouldn't have any interaction with your cosmetic materila and would not leach anything into the product.

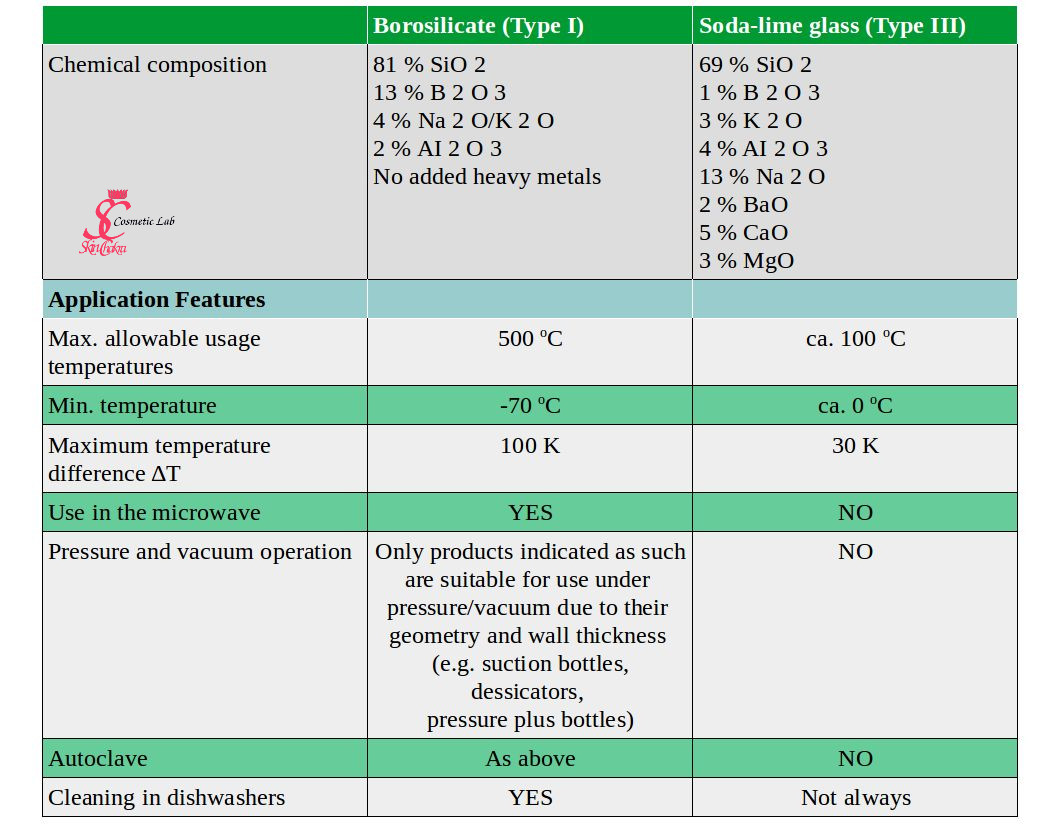

Glass is usually available in two basic classes (for jars and bottles):

- Borosilicate (which is the more resistant and inert type). This is known as type I and is offered as borosilicate or under several trade names such as Duran®, Pyrex® etc.

- Soda-lime which is the cheaper and less resistant type

I have packed their most important features in the following table

Their main difference (for your applications) is their temperature tolerance and their suitability for autoclaving

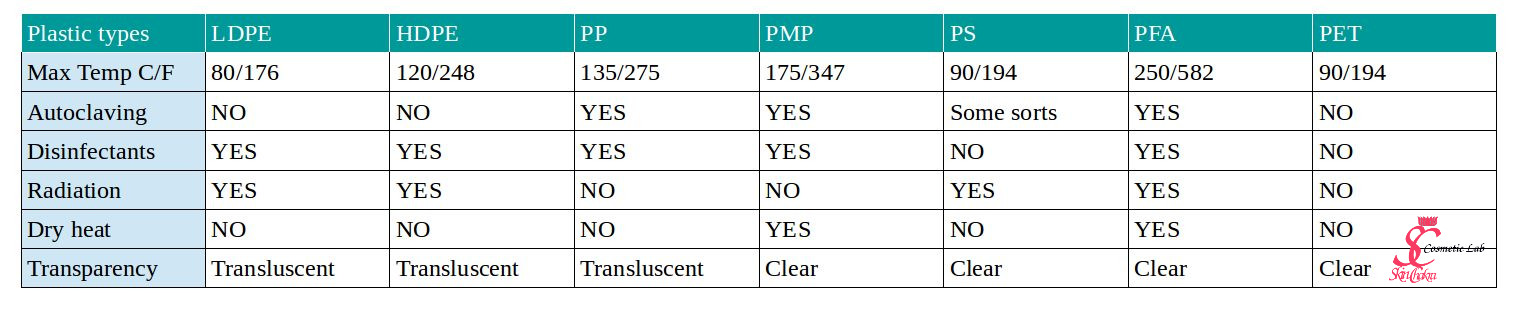

I have packed the basic plastic material (what you can find as jars and bottles) in the following table:

Whatever material you decide to chose for your stability testing, I would like to know about your experience and preferences. Feel free to share your experience with me.

Whatever material you decide to chose for your stability testing, I would like to know about your experience and preferences. Feel free to share your experience with me.

Thank you for being here and for sending me your comments and photos. Don't hesitate to post your questions and comments. I really enjoy your participation in our Facebook discussions.

Be Happy and have fun