Samstag, 23. Juli 2016

What you need to know about natural gums (part II): Gum blending

To read the part I of this post click here.

Apart from stability of a product, which is the first reason why we apply gums and hydrocolloids in our products, we expect from a gum to improve the texture and flow behaviour of the product.

In the first part of this post, you've seen that all of the gums we've used improve the stability of the product compared to the same emulsion made without any gum. However we've seen as well that not all of these gums create a smooth and silky texture.

In most cases and inorder to optimize the stability, the viscosity, flow behaviour and texture of an amulsion we need to blend gums together. This is called "synergetic blend" and we create am improved effect by blending at least two gums. The overall properties of the synergetic blend is superior to the properties of any of the individual gums.

For this study, we've blended xanthan gum which is the most widely used gum in skin and hair care with other gums used in part one of this study.

These are the gum blends we've used:

| gums | Ratio/Con. | |

| 1 | Solagum Ax | 0.5% |

| 2 | Xan-Tara | 0.5% (1:1) |

| 3 | Xan-Kon | 0.5% (1:1) |

| 4 | Xan-Sclerotium | 0.5% (1:1) |

| 5 | Xan-Trag | 0.5% (1:1) |

| 6 | Xan-Acacia | 0.5% (1:1) |

| 7 | Xan-LBG | 0.5% (1:1) |

| 8 | Xan-Carr | 0.5% (1:1) |

| 9 | Xan-Guar | 0.5% (1:1) |

Formulation was the simple and basic formulation as in the last part:

Phase A:

5.0% Plantasens® HE20

40.0% distilled water

Phase B:

19.5% Organic poppy seed oil

0.5% Tocopherol

0.1% Organic Rosemary CO2 extract

Phase C:

0.1% Drmofeel® PA-3

29.3% distilled water

Phase D:

0.5% gum blend (as in the above table)

4.0% 99.5% Glycerine

Phase E

1.0% Euxyl® K903

Sodium hydroxide to adjust the pH between 5.0-5.5

Procedure:

The procedure was a hot-cold-cold procedure:

1- Heat phase A in a water bath at 70-75 degrees. 2- Blend the emulsifier in water completely to a gel-like blend. Stop heating

2- Add the cold oil phase and blend.

3- Add the rest of the water phase (at room temperature) and blend

4- Homogenize for a few minutes

5- Disperse the gum in glycerine and add this to the emulsion as you stir the emulsion. Continue stirring for at least half an hour.

6- Add the preservative and adjust the pH between 5.0-5.5

Results:

We've measured the viscosities of the emulsions two days after production. Tested the stability by centrifuge (4000 rpm for 15 minutes) and tested the thermal stability @ 4 degrees and 45 degrees as well as 5 Freeze/thaw cycles. The texture and skin feel were tested subjectively.

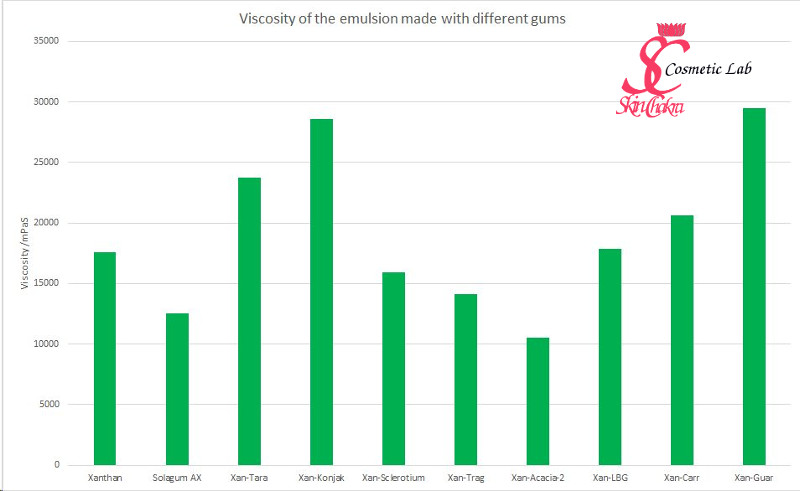

Let's see first how are the viscosities of the emulsions made with different gums. Viscosities are compared with teh viscosity of the emulsion made with xanthan gum as a solo gum.

Solagum AX is a proprietary blend of Xanthan gum and acacia gum which we've recently added to our online shop (you can imagine how excellent it works alone by the fact that it is added to our shop ![]() )

)

We've added this blend at 0.5% as it was.

For all other gums in the table, we made a 1:1 blend of two gums and then applied this blend at 0.5% in the emulsion.

As you can judge from the above diagram, some of these gum blends have a higher viscosity compared with xanthan gum used alone (additive effect). These include tara gum, konjak, carrageenan and guar gum. The blend with LBG has almost the same viscosity as xanthan gum alone but has a completely different texture.

Solagum AX , sclerotium, tragacanth and acacia samples have a lower viscosity to xanthan gum alone.

If viscosity would be your number one concern, then you know which gums to blend with xanthan gum to achieve your desired viscosity or to increase the viscosity of xanthan gum.

Most often however, you don't necessarily want a high viscosity. Apart from stability, a nice and smooth texture, a silky and non-soapy skin feel and a smooth flow without any clumps is more important than just a high viscosity.

Let us have a look at the appearance of these blends.

To refresh your memory, this is the texture created by xanthan gum as a solo gum (from the last part of this post).

Xanthan gum builds stable emulsions. It is in fact one of my number one choices when I test a new formulation. The skin feel and the texture it creates however, are not always quite desirable. As you may have experienced yourself, it creates a kind of soapiness over skin as you rub the emulsion over skin.

Solagum AX which is a proprietary blend of acacia and xanthan gum creates one of the most stable and nicest texture among all the gums we've tested. This gum blend combines the stabilizing properties of xanthan and the texture improvement of acacia gum in a synergetic way. Just look at the smooth texture.

Xanthan and tara gum blend creates an emulsion with a higher viscosity compared to xanthan gum alone. The texture is much better than the emulsion made with xanthan gum alone but not quite attractive as the emulsion made with solagum AX.

Thermal stability results were not quite satisfactory for this blend though. It means, we couldn't recommend this blend (at least this 1:1 ratio) for emulsion stabilisation.

Xanthan and konjak gum create a synergetic gel. As you can judge from the viscosity diagram, the viscosity of the emulsion is much higher compared to xanthan gum alone. The texture of the emulsion is more like a gel than like an emulsion however.

This blend is suitable when you want to make some cream gels but is not the best choice when you want a smooth and free flowing emulsion or cream.

When we blend sclerotium with xanthan gum, the viscosity of the emulsion is reduced compared to the emulsion made with xanthan gum alone. The texture however is much improved. Look at the silky and smooth appearance of the emulsion.

You can guess why we, from all gums in the world, have decided to offer sclerotium on our online shop.

This blend passed all our stability tests. This could be one of your gum blends when you're looking for a nice and smooth texture as well as a stable emulsion.

The next blend is a blend of xanthan and tragacanth gums (did you know that tragacanth gum is one of the most effective gums in hair care products?).

The viscosity of the emulsion is reduced compared to teh emulsion created with xanthan gum alone but the texture and the skin feel are improved quite outstanding. This blend as well passed all of our stability tests.

The next blend we tested was a 1:1 blend of xanthan and acacia gum (which is not exactly the same as Solagum AX ).

Here as well, the viscosity is reduced compared to the emulsion with xanthan alone but the texture and skin feel are improved. This emulsion passed most of our stability tests.

The next blend is xanthan and LBG (locust bean gum). This blend makes a gel with a viscosity almost identical to the emulsion made with xanthan gum alone but with a complete different texture and flow characteristics.

Xanthan and LBG create a gel. The texture is quite nice and smooth but the emulsion is rather a cream gel instead of a free flowing emulsion. This blend is quite a nice blend when you want to create stable cream-gels even at low oil phase concentrations.

The next blend is xanthan and carrageenan. This blend doesn't make any gel but increases the viscosity a little bit compared to the emulsion made by solo xanthan gum. The blend is much smoother compared to the emulsion stabilised by xanthan gum alone but not quite smooth as emulsions made with tragacanth, acacia or sclerotium.

The blend with xanthan and guar gum has the highest viscosity among all blends we've tested in this experiment. Although the blend is quite stable, the texture is not quite desirable. If your first aim in a certain project is a high viscosity, this is the blend you may want to try.

Summary of stability testing:

| Blend | Centrifuge | 4oC | 45oC | 5 F/T cycles |

| Solagum AX | + | ++ | ++ | ++ |

| Xan-Tara | + | ++ | - | - |

| Xan-Kon | - | ++ | + | + |

| Xan-Scl. | + | ++ | ++ | ++ |

| Xan-Trag | + | ++ | ++ | ++ |

| Xan-Acacia | - | ++ | ++ | ++ |

| Xan-LBG | - | ++ | + | ++ |

| Xan-Carr | ++ | ++ | ++ | ++ |

| Xan-Xan-Guar | + | ++ | + | ++ |

I hope this test would help you choose your gum blend for your next emulsion. Please keep in mind that this is a typical test result for a certain blend and procedure we've mentioned here. This could be expanded to more emulsions and blends but should not necessarily be adapted as a general rule and commandment. You shall choose your desired gum blend after a detailed stability testing and the impact on the factors important in your product concept.

Anyway this study could be haelpful for you as a very general guideline or starting point.

Feel free to send us your questions and comment either per mail or to our Facebook page.