Sonntag, 16. Oktober 2016

How to improve the stability of your gel scrubs

Have you ever experienced having an scrub where the suspended particles float on top or fall to the bottom of the container after a while?

If you have had this experience, then you probably have increased the gum concentration and have desperately realized that by increasing the gum concentration, you may only change the texture and building clumps but the exfoliant doesn't remain suspended at all.

Have you observed that products seem to have a runny consistency but still the suspended particles, vitamin microspheres or the exfoliant remains perfectly suspended?

What makes a suspension stable despite the apparent low viscosity of the carrier?

Well, what keeps the particles suspended is indeed not a high viscosity but another physical parameter called "yield stress".

It is the parameter that makes some solid-like product flow (become fluid) by application of a certain amount of force/pressure.

Let me explain it in simple words. When you apply pressure to your toothpaste tube the toothpase flows out of the tube but then remains staying on the toothbrush (when the product is correctly designed, which hopefully is the case). The mayonnaise runs out of the bottle as you shake the bottle or press the tube but then remains on your toast or fried chickens, it doesn't run over the plate. Is that right?

It means your toothpaste or the mayonnaise have a kind of solid-like structure and they don't flow automatically until you apply a certain amount of force. Under this force/pressure they become like a liquid and flow but after the force is stopped/removed they become solid-like again.

Does this make sense?

This force is called "yield stress" in physics and is the minimum required force to make the fluid flow.

So what?

Well, you may ask: what does mayonnaise have in common with my facial scrub?

The answer is: YIELD STRESS

Yield stress is the characteristics that keeps particles suspended and it is not necessarily related to viscosity. It means you may have a medium viscosity product where your exfoliants remain perfectly suspended whereas in another product with a much higher viscosity the particles sediment at the bottom of the container.

Yield stress is one of the parameter that makes the difference between natural gums and this is something to be considered when you're designing and formulating cosmetics (as well as food, pharmaceuticals, painst, inks and many other products).

To explain this complex parameter in an easy to understand way, we've played with various natural gums and suspended luffah and cranberry seed powder in the gels and then measured the viscosity. The exfoliants remain perfectly suspended in some of these gels and sediment in some . Our viscosity measurements show that a higher viscosity does not necessarily leads to a more stable suspension and that some gums by nature lead to a higher yield stress compared to other gums.

Understanding this parameter is the key to product design and formulation when you're formulating almost all cosmetic products .

Before we proceed, you may want to have a look at our previous posts and experiments with natural gums:

What you need to know about natural gums (part II): Gum blending

What you need to know about natural gums (part I)

To show you that a higher viscosity does not necessarily cause to a higher yield stress (and better suspension) we prepared very basic gels with exactly the same formulation and just varying the gum. We measured the viscosity and observed the stability of the suspensions (visually) afetr 3 weeks.

This is our frame formulation for the scrub

Phase A

Gum 1.5%

Glycerine 99.0% 5.0%

Phase B

Distilled water 88.9%

Dermofeel PA-3 0.1%

Dermosoft 1388 3.5%

Phase C

Lactic acid to adjust the pH

Phase D

Exfoliant 1.0%

Procedure :

A- Blend the gum and glycerine in a small beaker

B- Blend all ingredients of phase B @RT

C- Disperse gum-glycerine blend in the water phase. Stir for some 20 minutes for the gum to totally hydrate

D- Adjust the pH with lactic acid between 5.0-5.5

E- Disperse the exfoliant and blend gently to avoid air bubbles. We've used two separate exfoliants: cranberry seed powder and luffah (is the green coloured exfoliant in the photos)

We made all samples @RT. If you've noticed the gum concentration, we remained by 1.5%. If you can not get a stable gel at a concentration between 1.5-2.0% gum, there is no reason to increase the gum concentration to 5.0% and more. It certianly wouldn't work. Gums should work in a certain system at low concentrations (0.1-2.5%) . Increasing the concentration would only make clumps without increasing the stability or improving the get structure or texture and suspending efficacy.

These are the gums we've used:

Xanthan gum

Solagum AX (a proprietary blend of xanthan and acacia gum)

Satiagel (a proprietary Carrageenan blend)

LBG (Locust bean gum)

Sucraclear HC-31 ( a proprietary blend of Cellulose gum & Carageenan & LBG & Sucrose)

Konjak gum

Guar gum

Tragaccanth gum

Tara gum

Acacia gum

Carrageenan (iota)

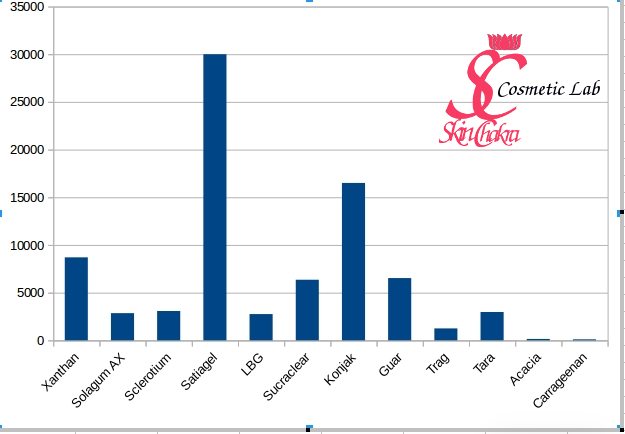

Here are our results. First have a look at the viscosity diagram

As you can see, the viscosities are quite different varying from a water like viscosity (for carrageenan and acacia gum) to 30,000 mPaS for Satiagel. (we tested all gums without adding any electrolyte to the solutions).

Except from Satiagel which is a proprietary blend and has made a real hard gel (this is the gum I've used for the hair styling gel in the certificate of natural hair care course) the rest doesn't make any real gel in a standalone formulation.

If a higher viscosity would automatically lead to a better suspension and more stable scrubs, one would expect that samples with a higher viscosity be more stable than those with a lower viscosity.

This is true only for carrageenan and acacia gum solutions. They both had a water-like viscosity and a very poor suspension. They couldn't suspend the exfoliant at all and the particles sedimented after a few minutes to few hours.

The upper photos are immediately after suspension, the lower photos after 3 weeks storage @RT.

Acacia gum

Apart from these two gums that had an extraordinary low viscosity, the rest of the gums show confusing results.

The viscosity of the solution made with guar gum for example, is much higher than samples made with Solagum AX, sclerotium or tragaccanth. Surprisingly however, the guar scrubs were unstable whereas the scrubs made with other 3 gums were perfectly stable after 3 weeks (now that I'm writing this post, 5 weeks are passes)

It is the same with tara gum and LBG. Both of them having a similar viscosity and a much higher viscosity than the sample made with tragacanth. Whereas the tragaccanth sample is stable after 3 weeks, both tara gum and LBG samples are sedimented.

Satiagel which is a proprietary blend of carrageenans from Cargill makes a real stiff gel. It created the highest viscosity of all the gums we've tested. I wouldn't use this gum for a scrub as a standalone gum and would probably blend it with gums such as guar or LBG to create a soft and flowing gel with enough yield stress to hold the suspended particles.

Satiagel

Xanthan gum, well it is xanthan gum and a handy dandy gum for almost all purposes. It creates a soft blend with acceptable suspending ability. It could be blended with all other gums to modify the flow of the solution depending on what you expect and what is your desired packaging.

Xanthan gum

Sucraclear is a proprietary blend of Alfachemicals and is easy to work with. It doesn't create a very high viscosity but the scrubs are perfectly stable even at a moderate viscosity.

Sucraclear

Konjak creates the second highest viscosity and a perfectly stable scrub even at room temperature.

Konjak gum

I would probably blend konjak with other gums for a synergy of flow and yield stress.

I hope this experiment can help you design your scrubs and other products needing a suspending material. Even if most gums are available to an affordable price, the golden rule by formulation is:

AS much as needed

As low as possible

Increasing the gum concentration to 5% would not improve the stability if you've chosen the wrong gum for your product it would only negatively affect the texture of the product.

Don't hesitate to send us your photos, comments and questions either per mail or by posting your photos on our Facebook page or tagging us on Instagram.

BeHappy and have fun