Freitag, 19. Mai 2017

How to make a shower gel

Despite all the beauty and popularity of hand made soap and clay cleansers, liquid shower gels are sometimes indispensible and much easier to carry and to use (specially where you're on the go, on travel or in a gym).

Here we're sharing a (not quite) KISS formulation with you. You can expand the formulation and more extracts or even blend other surfactants into this simple and basic formulation.

When working with surfactants, making foam is inevitable. The more you blend the more foam you create and the higher the viscosity, the longer the foam resists. In an industrial scale, mixers are equipped with vacuum that removes the foam or the product passes through a continuous centrifuge to get rid of the foam before the product is filled in bottles. In a small scale an in an artisanal lab, the best way to make products without air bubbles and foam is to avoid their formation at all (it is much easier to say than to do). There are however benchtop and laboratory scale centrifuges (or vacuum pums) that can help you create a product without foam if you insist upon getting rid of air bubbles trapped in a shampoo or shower gel.

This photo shows the same product in a beaker (without any treatment) and in a bottle after being centrifuged. You can easily distinguish the difference between the samples before and after centrifuge.

Anyway, back to our basic formulation for a shower gel . In conventional and mainstream personal care, the viscosity is provided by synthetic polymers or salt. Synthetic polymers and copolymers such as acrylates are absolutely nonacceptable in natural cosmetics and salt wouldn't have any impact on the viscosity when you're working with "natural" surfactants and co-surfactants. The only way to modify the viscosity of a shower gel or shampoo, when working in a "natural and organic" concept is working with natural gums.

Gum dispersion is the most critical step in making organic shampoos and shower gels. If the gum doesn't disperse efficiently and homogeneously, the product would be unstable and undergo phase separation or sedimentation. We're using a proprietary blend for our shampoo and shower gel formulations: Solagum AX which is a proprietary blend of acacia and xanthan gum.

This gum disperses perfectly in water @ room temperature but you can heat the water for an easier dispersion as well (specially if you are not using a turbo mixer).

Read our previous post about gum dispersion

You can use a homogenizer, an overhead mixer, sometimes a magnetic stirrer (small quantities and low concentrations of gum), an immersion blender (the least suitable instrument) or a spatula or whisk (for small quantities) to fully disperse the gum. We usually pre-disperse the gum in glycerine (at least 99% assay) to avoid its clumping when it is added to water. In this way, the gum is easily dispersed in water without any need for a high shear mixer.

Formulation:

Phase A

Coco glucoside 15,0%

Decyl Glucoside 5.0%

Euxyl K903 0,8%

Organic petitgrain essential oil 1,0%

Phase B

Organic cornflower hydrosol (preserved) to 100%

Hydroglyceric elder flower extract 2,5%

Hydroglyceric meadow sweet and bilberry extract 2,0%

Sodium lactate 2,0%

Panthenol 1,0%

Dermofeel PA-3 0,1%

Organic aloe juice powder (200:1) 0,5%

Phase C

Organic and palm free glycerine 5,0%

Solagum AX 2,0%

Phase D

Lactic acid 80% to adjust the pH

Procedure:

1- Blend the gum and glycerine in a small beaker

2- Blend phase A and phase B separately in two beakers at room temperature. We usually blend our surfactant phase with a magnetic stirrer. You can either use a magnetic stirrer or a spatula for blending the gum. Try to avoid agitation and foam making.

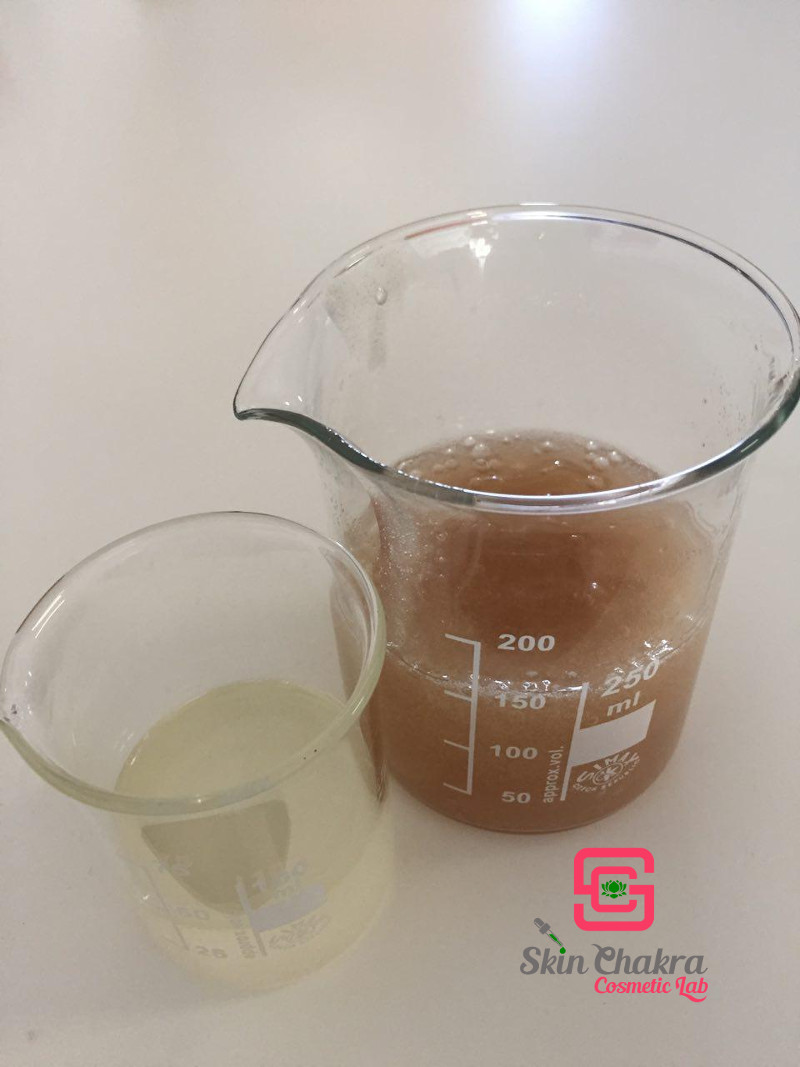

The colour of the water phase is because of the hydroglyceric extracts we've used.

3- Disperse the gum-glycerine in the water phase. We usually use an overhead mixer. You can use any of : an overhead mixer, a magnetic stirrer, a broad spatula or a whisk when you're working in a small scale.

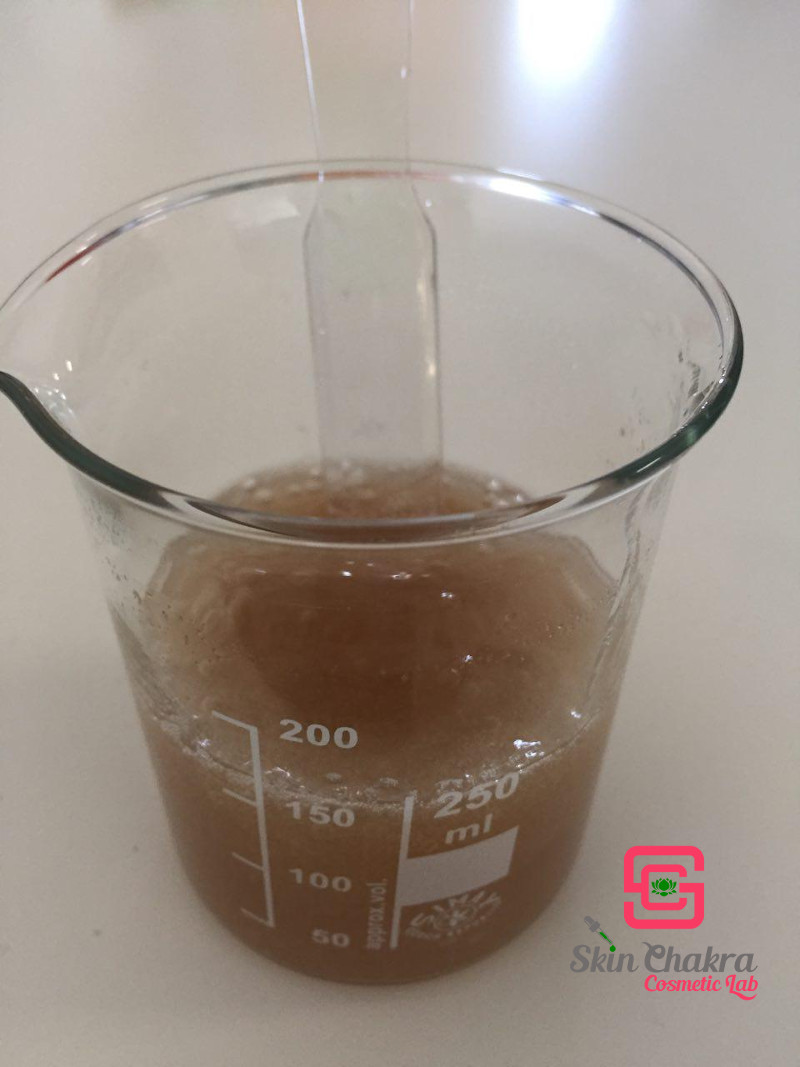

4- Slowly and little by little, add the surfactant phase to the water-gum phase. Blend after each addition.

5- When all of the surfactant is added to the water phase prepare a 10% dilution of the shower gel in distilled water. In our case the pH was 6,85 and we've added 0,5% of 80% lactic acid to reduce the pH to 5,10. Since we've used hydroglyceric extract with high anthocyanidin content (the colour depends on the pH), the colour of the shower gel changes after reducing the pH.

Despite all our efforts, the freshly prepared shower gel has some air bubbles and foam.

You can leave this as it is, or leave it in a well covered beaker for a few days. The foam diminishes in a few days but does not completely disappear. We've used a small centrifuge to get rid of the foam.

If you're inspired by this tutorial feel free to send us your photos and comment either per mail or to our Facebook page. If you post any photos on Instagram, don't forget to tag @SkinChakra.