Spray emulsions and cold process emulsions are among my absolute favourites and sucrose stearate is one of the few "natural" emulsifiers that combines both.

I have prepared and shared many cold process emulsions with this emulsifier in the past but recently I tested a new process and I was quite astonished about the outcome.

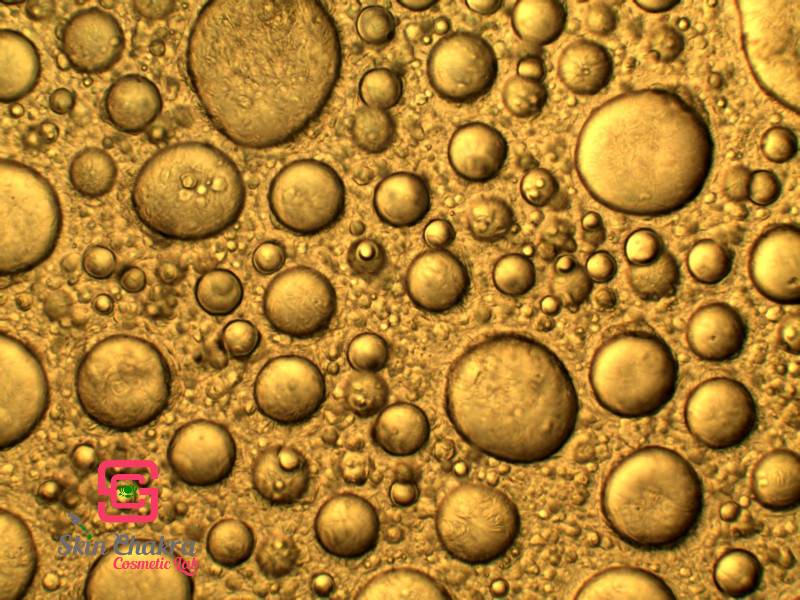

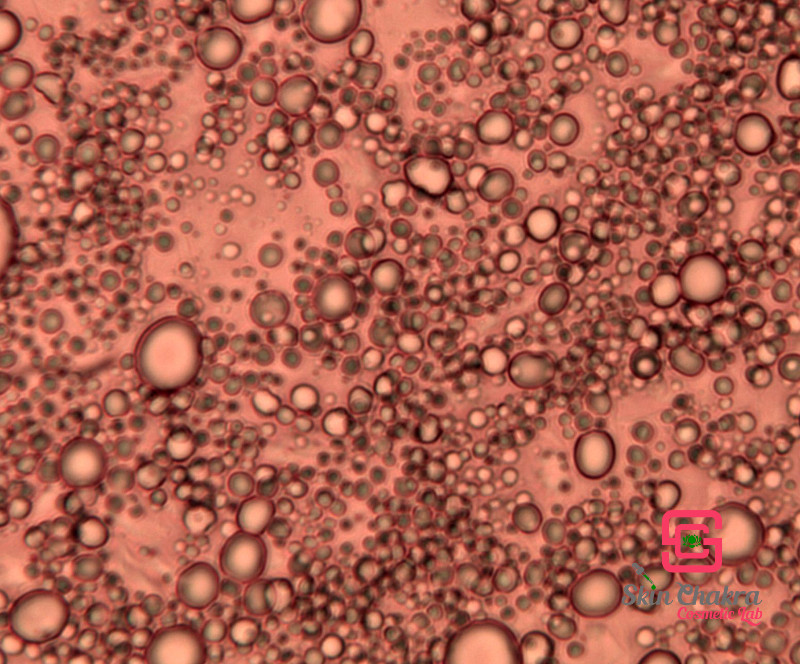

Let me explain that the key to a stable emulsion is the particle size. The smaller the emulsion droplets, the longer stable the emulsion and the better the texture. Another factor in emulsion stability is a narrow particle size distribution. This means that we need an emulsion with particles (droplets) with the same size range.

These properties are usually easily achieved with heat but when we cold process, we need to increase the mechanical agitation to compensate for the absence of heating.

In clear words: you need a stronger stirring (homogenization) when you cold process.

This is an unstable emulsion with a broad particle size distribution and large particles

This is a stable emulsion with a much smaller particle size

Having that said, let's jump to our emulsion.

This is an oil-in-glycerine emulsification process. Something most of you have probably not heard of. It is used for low oil (5-8%) concentration emulsions (readers in hot and humid regions, this is your call!!) with an amazingly smooth and nice texture.

The principle is:

- Blending the emulsifier with glycerine to make a paste.

- Adding the oil phase to the glycerine phase to make a pre-emulsion

- Adding the pre-emulsion to the water phase and make the final emulsion

Just follow this procedure to create an amazing light-feel emulsion with a low oil content.

Ingredients:

| Phase A |

|

| Organic and palm-free glycerine |

5,0% |

| Sucrose stearate |

3,0% |

| Phase B |

|

| Buriti oil |

4,0% |

| Carrot CO2 extract |

1,0% |

| Amaranth CO2 extract |

1,0% |

| Natural tocopherols |

0,5% |

| Rosemary CO2 extract |

0,1% |

| antimicrobial blend |

0,1% |

| alpha-bisabolol |

0,2% |

| Phase C |

|

| Yarrow hydrosol |

to 100,0% |

| Vegeluron |

3,0% |

| Ronacare renoumer |

2,0% |

| Aloe leaf extract powder |

1,0% |

| Sodium PCA |

1,0% |

| Sodium lactate |

1,0% |

| Natural chelator PA-3 |

0,1% |

| Phase D |

|

| Solagum AX |

0,4% |

| Sclerotium |

0,1% |

| Hyaluron high MW |

0,1% |

| Phase E |

|

| Arginine |

(to adjust the pH) |

| Versatile preservative TBG |

1,0% |

| Phase F |

|

| Lemon zest oil |

0,1% |

| Grapefruit oil |

0,1% |

| Green mandarine oil |

0,3% |

Procedure:

1- Blend sucrose cocoate and glycerine at RT in a beaker. Let it stand for 1-2 hours. It becomes a thick paste

2- Blend the oil phase in another beaker at RT.

3- Blend the water phase (C) in another beaker and disperse phase D in phase C.

4- After 1-2 hours and after sucrose stearate phase is a homogeneous phase slowly add the oil phase to the glycerine phase in small aliquotes and blend after each addition. You'll have a high viscosity pre-emulsion at the end of this step

5- Now slowly add the pre-emulsion to the water phase (C+D) while stirring. After the addition is finished homogenize for 2-4 minutes.

6- Prepare a 10% dilution in distilled water and measure the pH. In our case it was about 4,5. This is too low for our preservative system. We added L-Arginine (the 100% powder) to the emulsion to increase the pH to around 6 and then added the preservative. The preservative has reduced the pH to 5,4 which is in our range. You may need to increase or decrease the pH before and after adding the preservative according to your preservative system.

7- Add the essential oil blend.

8- Take your stability and micro kit samples and fill the rest in a spray bottle.

9- Enjoy the skin feel and the nourishing properties of this carotenoid rich emulsion.

BeHappy and have fun