Sonntag, 16. Juni 2019

The revolution has started: Bioplastic and the cosmetic industry

The word "plastic" is the curse of the decade. Watching the heartbreaking photos and videos of dead pelicans, whales and dolphins with kgs of plastic in their stomach should be a wake-up call for all of us.

Specifically in the "natural" cosmetic industry, plastic is a polarizing theme and raises discussions and reactions which are more emotional than rational.

In all our passion for the environment, we easily forget that the manufacturing of plastic and the process of polymerization has enabled us to mass market hygienic products that were not affordable and accessible to the public and expanded a trade horizon that was not possible before the plastic.

Despite many passionate skincare entrepreneurs I don't see the plastic issue as just black or white and believe in many grey shades in between.

As a supplier of raw material, we have a clear policy towards plastic. As much as we try to satisfy all customer demands and wishes, our first priority is to delivery the ingredients at the lowest possible cost and highest possible safety/accuracy. We use glass when we know the ingredient might interact with plastic (essential oils and CO2 extracts with a high content of essential oils) but use plastic for the rest of the material. We are constantly looking to improve our packaging and logistics towards a more sustainable system but this is nothing anybody can do overnight. As James Clear explains in his interesting book "atomic habits", with 1% improvement per day, you're 37% better at the end of the year.

Anyway, like it or not, at the moment there is no way around plastic in the cosmetic industry. If you are a premium brand you might prefer to avoid plastic completely and ship your products only and only in glass containers around the world (accepting the higher costs of both manufacturing and transport and the higher risks of damage). Let's keep in mind that even the most environmental and CO2-neutral enthusiasts hate having broken glass in their bathroom and in their shower cabin.

Just last week, I have received 4 plant extract samples from an amazing French company. They have been producing premium natural ingredients long before "natural" became so fashionable. As expected from such a high calibre company, they sent the samples in glass bottles and guess what: The parcel was on the way less than 1000 kms and only on the road from France to our lab in Bavaria, yet one of the bottles was broken to shard. No need to mention that all of the content and the documents includedin the box were useless and on top of that I cut my finger as I tried to clear the mess.

Good news

Even the mainstream industry and the big players on the market have realized that they need to take some steps towards renewable and more sustainable raw material. These are only baby steps but now that the awareness is there, they can only move forward. The production capacity is very low and the choice is very limited at the moment, but everybody who is somebody in the plastic world is doing something and huge public and private funds are dedicated to research. It can only become better.

What is bioplastic?

Well, this is a very broad term and there are various material that are different in terms of biodegradability and sustainability.

Disclaimer: I'm no expert of plastic at all. This is the information we have received from our suppliers and from visiting different exhibitions and trade fairs. Please bear with me if you are a plastic expert and my explanation seems very amateur like and please don't hesitate to correct me if you detect any mistake in my explanation.

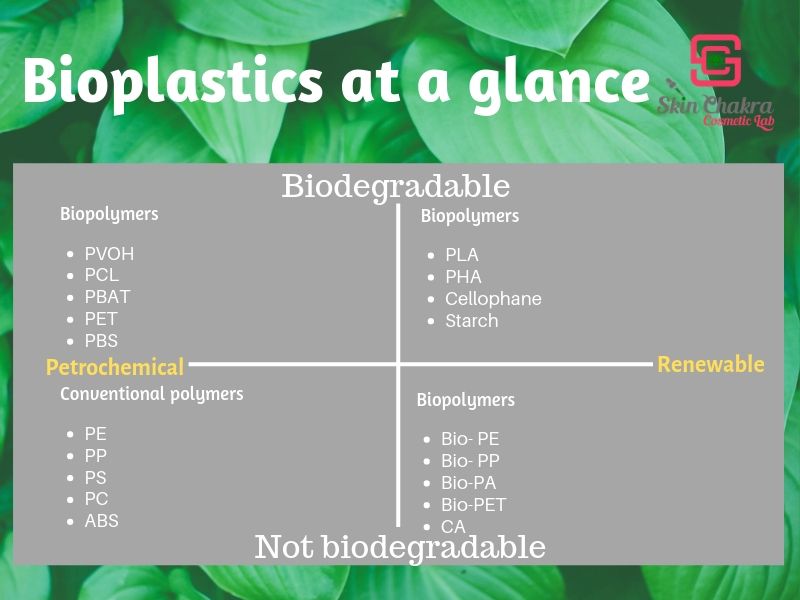

Available (at the moment) material is depicted in the below diagram to give you a rough idea of which types of plastic are used in packaging and a very broad classification of them in terms of:

1- the source: renewable vs petrochemical

2- biodegradability

According to European bioplastics' definition: bioplastics are biobased, biodegradable or both.

This means in simple words, bioplastic is one of:

- Biobased or partially biobased plastics that do NOT biodegrade.

- Biobased plastics that are biodegradable.

- Plastics that are petrochemical based and are biodegradable.

You may ask yourself: now that bioplastics are available, why don't we switch immediately and all at once from conventional to bioplastic?

The reason is:

- the available material is not yet enough to cover the whole consumption

- price

- compatibility of bioplastic with the available manufacturing machines

- hydrilytic and thermal limitations of bioplastics vs conventional plastic

- most bioplastics are not compatible with the other ones

Available sources:

One of the most fascinating sources, is ethanol. Ethanol is available in various grades. It could be directly distilled from food sources (they way they distillate biofuel from food such as corn, potato, sugar cane etc). Well if you ask me, in a world that 1 out of 7 inhabitants do not have enough food to lead a healthy active life, this is a sin to use food for making biofuel or bioplastic (this is my private and personal point of view and most of you may not agree with me. We can still remain civilized friends if we disagree on certain aspects, can't we?)

Well, I was told that the sugar cane is practically useless after the third distillation cycle. Well, at least useless for biofuel. It is practically trash. Now the fascinating part is here: you can make bioplastic from the sugarcane after the third distillation. This is the ultimate sustainability and reasonable use of resources if you ask me.

A step further:

Some creative manufacturers, move one step further and blend food waste (coffee waste, sawdust, nut shells, cork etc.) to the bioplastic.

Wood and cork:

wood and cork seem to be very fashionable in packaging right now. Keep im mind that you can not safely pack any cosmetic material (raw material or finished product) in a container made of wood or cork without the risk of contamination or chemical degradation. What you see is practically an optical push-up to ignite the impression of "natural" in consumers' lymbic system. There are beautiful and elegant products on the market now and the trend is increasing. You must know however, that this is only the surfact of the packaging and the body of the container must be somehow coated to guarantee the safety/stability of the product.

Wood and corck optic are blended with different plastic (conventional or bioplastic) material for a more "natural" impression

I hope I could give you a starting point to understand different shades of bioplastic. The future looks bright and promising and hopefully we'll soon have containers that are beautiful, practical, more sustainable and avilable in small quantities for startups and Indie beauty.

Further reading:

I found the data and statistic in the following links very informative and useful:

https://docs.european-bioplastics.org/publications/EUBP_Facts_and_figures.pdf

http://www.sciepub.com/portal/downloads?doi=10.12691/jpbpc-2-4-5&filename=jpbpc-2-4-5.pdf

BeHappy and have fun