Click here for part I.

The fascinating fact about carbomer is its becoming gel only after neutralization. It means you can prepare a mucillage in advance and keep it (if preserved) even for weeks and then use it according to your requirements, adding all your ingredients and additives and neutralizing at the very last step.

I always have a 0,5% mucillage in stock which I prepare and apply weekly. Once you've learned how to prepare the mucillage and after you've prepared your first couple of batches it becomes as easy as dissolving sugar in water.

So let's start with the essentials of preparing a mucillage:

1- Prepare your first batches in as small quantities as possible (50 or 100 ml would be the best). It's a pitty if something goes wrong and you have to discard a 500 ml batch.

2- The most important part of dispersing carbomer is to avoid clumps (similar to Xanthan gum or cmc or tylose). Once clumps are build, it is almost impossible to rescue the mucillage unless you have a very effective turbo mixer or ultrasound mixer.

a 0,5% Mucillage is a reasonable starting concentration. Even if you add additives later on (fragrance oil, color, emollients) the final preparation has a gel like consistency.

Clumps are build as the outer surface becomes wet and swells while the inner part remains dry. The thinner a film is, the easier it is that the whole volume gets wet and the less the chance of building clumps.

a) Working with alcohol

The easiest way to prepare a mucillage is to disperse carbomer in alcohol (ethanol or isopropyl alcohol both work). If your formulation contains alcohol or can tolerate alcohol, disperse the carbomer in alcohol first.

For an example of dispersing carbomer in alcohol have a look at our tutorial "Happy Feet".

The best way to prepare Carbomer is applying a magnetic stirrer but don't be disappointed if you don't have any, you can still prepare the dispersion.

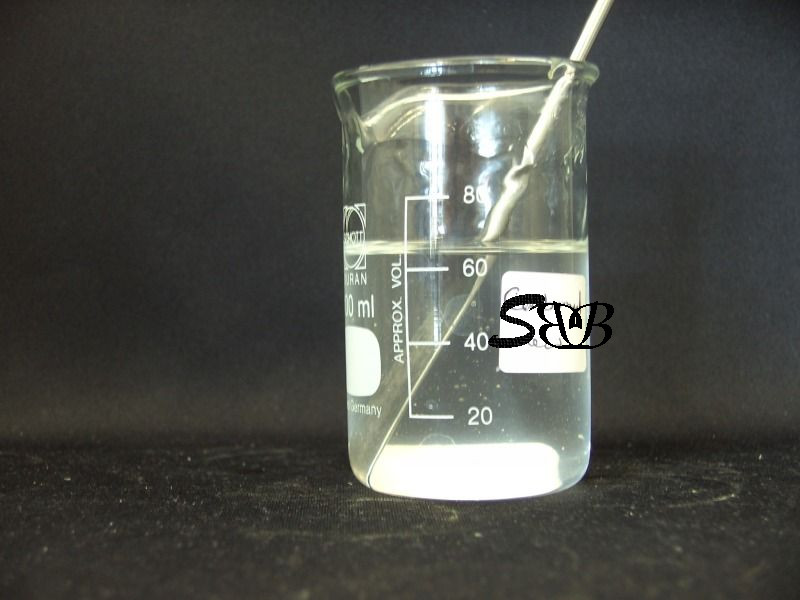

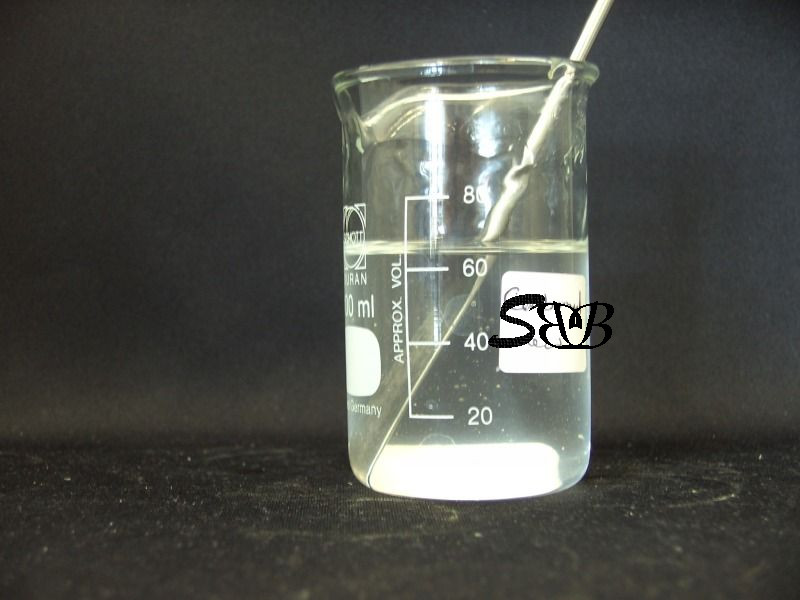

Measure your alcohol into a beaker (by weight or by volume).

Sprinkle carbomer over the surface of alcohol. (if you're using a magnetic stirrer sprinkle carbomer as the magnetic stirrer is off). Add your carbomer in small portions. Wait until the carbomer over the surface is wetted. You'll observe a change in the appearance. The white powder becomes translucent as it wets.

After the film is wet and became translucent turn the stirrer on for a short time or stir with hand for a few seconds. This moves the wet film from the surface to the bulk of the alcohol. Then stop stirring and add another portion. Continue this process until you've applied the whole carbomer. Then stir for another couple of minutes and make sure you have no clumps. At this stage and before adding water you've still a chance of breaking the clumps with a glass rod or spatula.

After you're satisfied with the mixture add the required amount of water under stirring. You'll still have a non-homogeneous and non transparent medium viscosity mixture.

You can use this mucillage immediately or preserve and keep it in a closed bottle for later application.

b) alcohol free preparations

If you don't have any alcohol in your formulation, preparing mucillage is a little bit more tricky.

Keep in mind that the higher the water temperature, the faster and the easier the wetting. And the larger the surface of the water the easier the dispersion and the wetting.

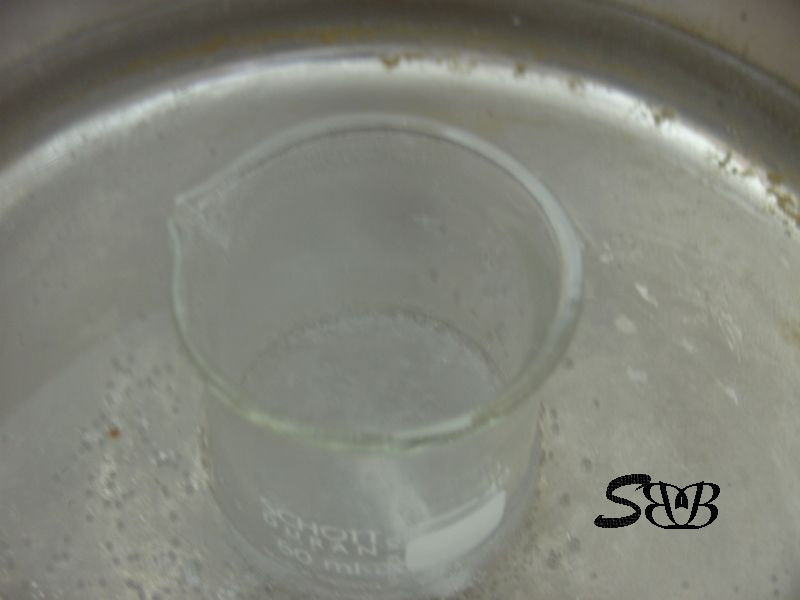

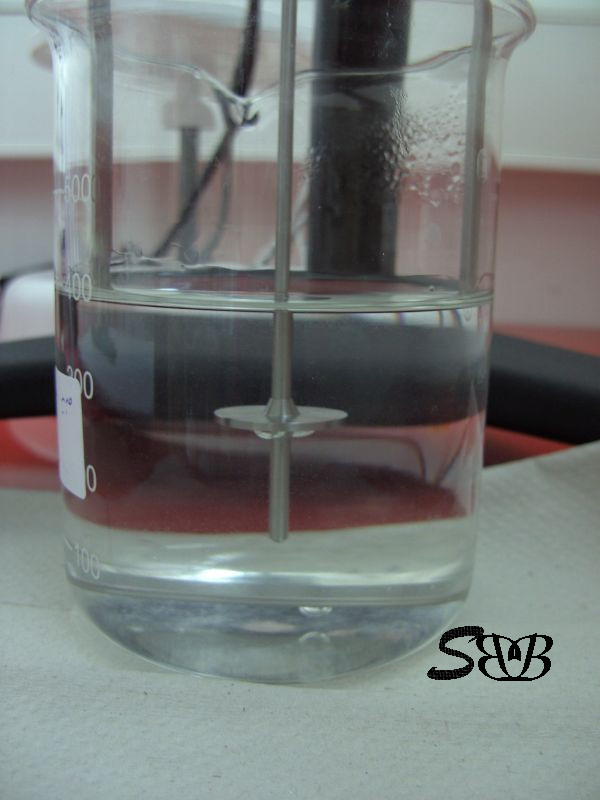

Add your water to a beaker with a large surface (a 500 ml beaker works well). You don't need an exact amount of water because water is going to evaporate, but you need the exact weight of your beaker (and the magnet rod if you're applying one) so that you can compensate the water loss at the end.

Heat up the water (preferably in a water bath). The water bath should be around 80 degrees Celsius. Let the water get warm. Sprinkle small amounts of carbomer over the surface of the water. Sprinkle so much that a very thin film covers the water surface.

Wait until this portion is completely wet. The powder becomes translucent as it wets.

Now turn the stirrer for a short time or stir with a glass rod until the wet powder is transfered from the surface to the bulk.

Stop stirring and add another portion to the surface. Repeat the procedure: "Adding powder to surface, waiting till the powder is wet, stirring" until the whole powder is dispersed in water.

Stop heating and stir with a stirrer or with a glass rod.

Add the lost water and bring your mucillage to 0,5% concentration.

This is the translucent, medium viscosity mucillage. Use it immediately or store it in a well closed bottle for later use. In the latter case you should apply a suitable preservative. We recommend Euxyl PE9010 for Carbomed preparations.

c) Neutralisation

It is advisable to add all your other ingredients (preservative, fragrance, colorants, dispersed particles etc.) before neutralization.

Carbomer mucillage has an acidic pH of around 3,5. Only after neutralization the polymer chains are organized and a clear, stable, high viscosity gel is formed. (Look at part I for a diagram of viscosity vs. pH).

Neutralization is performed with an alkaline solution. This could be NaOH (the same thing we prepare our lye solutions with) or Triethanolamine or any other base. For us soap makers, neutralization with NaOH is the most comfortable and suitable method.

Although the lye solution is generally much less concentrated (10,0%) compared to the lye solution for soap making, I still recommend you to reread our advisory post regarding safe handling of NaOH.

Generally, only a few drops of NaOH (a 10,0% solution) are enough to increase the pH from around 3,5 to around 6,5-7,0. Add dropwise and stir gently after each drop to check the pH, viscosity and clarity of the mixture. Even after addition of the first drop a significant change in viscosity and clarity happens. Unless you prefer to have air bubbles in the gel try to stir very gently to avoid bringing bubbles. It is very hard to get rid of air bubbles in such a gel with a high viscosity and yield stress.

Check the pH after each addition with a pH indicator paper or an electronic pH-meter attached to a glass electrode.

If you over neutralize, the viscosity will decrease and the gel becomes slightly translucent. This is wished for specific products such as cuticle softeners but generally for bath & body products a max. pH of 7 is wished.

The gel, if preserved correctly would be stable over years. I have gels for over 5 years but the shelf life of the product depends on your other ingredients as well.

This was a basic to working with carbomer. In coming tutorials we're going to prepare interesting products with carbomer.

You can purchase all necessary ingredients and tools in SkinChakra® Online shop.

BeHappy and have fun

Swettis Beauty Blog am : Working with Carbomer (part I)

skinchakra.eu am : PingBack