Freitag, 9. Dezember 2016

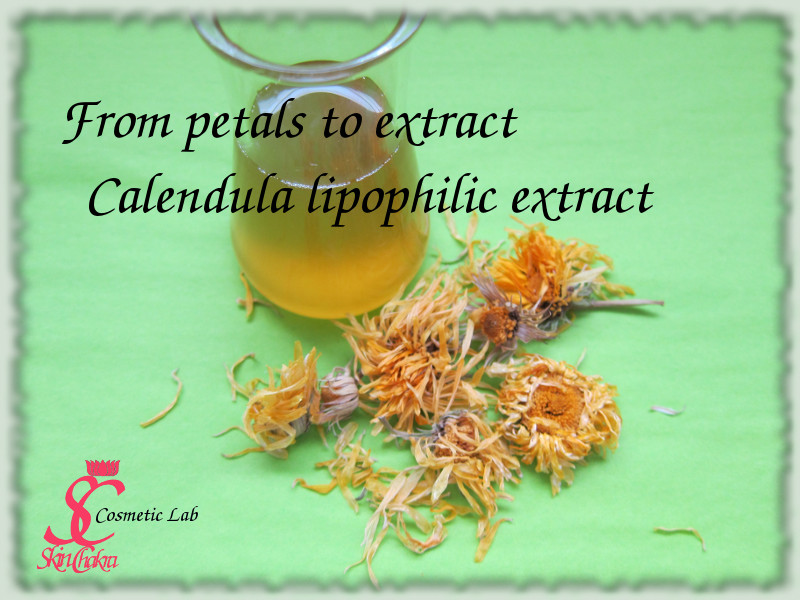

From petals to extract: How to make Calendula extract (lipophilic)

As I wrote this and this blog posts earlier this year, there were different reactions from raised eyebrows to questions such as: "why on earth using castor oil for extraction and infusion?"

About castor oil

Castor oil is indeed a very modest and undervalued oil in hair and skin care. Unless you're a soap maker, perhaps you've never worked with it.

Castor oil with the INCI name: Ricinus communis seed oil is extracted (by cold press, hot press, solvent extraction or a blend of all of these methods) from the seeds of castor a plant indigenous to Eastern Africa and India.

Although the seeds are toxic (they contain a water soluble toxin), the oil is toxin-free and even edible (well not quite a delicacy).

Castor oil and its derivatives are used in paint, fuel, lubricant, pharmaceuticals (in oil based eye drops for instance) and cosmetics industry (not to mention the application of a castor oil derivative in the chocolate industry).

The oil is colourless and has a very decent scent. These are two fundamental requirements for making herbal infusions and extracts. The main component of castor oil is a unique fatty acid ricinoleic acid which is a sister of oleic acid (C18:1) and an omega-3 fatty acid (mainly found in castor oil). Ca 70-90% of castor oil consists of ricinoleic acid. Stearic acid, oleic acid and linoleic acid are present as well at low concentrations.

Castor oil contains phytosterols, most of all beta-sitosterol, stigmasterol, campesterol and delta5-avenasterol.

It contains about 700 ppm tocopherol (mainly delta and gamma tocopherol).

Castor oil has an outstanding thermal and oxidation stability and this is another advantage for its application as a carrier oil. One hardly uses oxidation sensitive oils such as pomegranate seed oil or linseed oil for extraction. On top of all of these advantages, it has a very reasonable and modest price.

Castor oil has a high viscosity and low spreadability. It is hardly applicable as a standalone oil because of the greasy skin feel but combined with other oils, it makes a lovely blend for almost every hair and skin application. It can however easily penetrate the intercelluar horny layer.

Castor oil has antimicrobial properties (thanks to ricinoleic acid). Although having a heavy skin feel, castor oil adds shine and gloss to hair and skin and it is a main component of lip gloss and lipsticks (both as a pigment dispersant and as a gloss additive). It has gained popularity during the last decades as a skin and hair care product and not just as a shine additive. It is extremely useful in oil cleansers, in pampering dry and itchy skin and scalp and apparently in treatment of age spots 1.

Are these not enough reasons to use it as a carrier oil in macerations and extracts?

We've made several extracts in organic castor oil during the last years and just a few months ago we made a new calendula extract which I'm going to share with you.

There is no need to tell you why we chose calendula. This extract could be applied in head to toe products such as:

- Hair care and styling products such as oils,balms, conditioners or putties

- Scalp treatments and conditioning shampoos

- shower creams for dry and agitated skin

- shower oil or bath oil

- facial cleansing oil, oleogel, cleansing balm or milk

- body oil, butter or emulsions, even massage oil

- lip stick and lip gloss

- Baby care products such as balms, bath oil, cleansing oil

- foot care balms and emulsions

Keep in mind that the extract is applied in dosages between 1-5%. It means you're not feeling the high viscosity and low spreadability of castor oil but you'll have its skin and hair care benefits as well as the shine it adds to lip care products or to your hair.

You are however free to swap the castor oil in this tutorial with any other oil of your choice: Sunflower, macadamia, jojoba or even more heat sensitive oils (since we make cold process extraction).

Before we start

Working with extracts is a time consuming and delicate business. Only those who have created their own extracts know what I mean. You are working with plant material, an excellent food source for contaminants. It is extremely important to follow a GMP regime and be meticulous with your material and instruments to avoid later frustration when you have to discard a beautiful extract that is unfortunately contaminated (don't ask how I know it).

In case of lipophilic extract, it is highly important that you have absolutely no water in the system. Even the smalles concentrations of water (a few drops) may cause contamination. Be sure that all of your instruments, vessels, filters, bottles etc are completely dry. Put them in the oven for a few hours to make sure they have no traces of water.

This is the same for your plant material specially when you use plant parts that you've gathered and dried yourself. Take your time to completely dry the plant otherwise you'll have contamination even before the filtration is finished.

How to

Although there is no "must" and "shall not" and no fixed ratio for plant materil:oil, generally a 1:10 ratio is a good place to start. Meaning 1 part plant material to 10 part carrier oil. The ratio can vary from plant to plant and from carrier to carrier. In this case, a 1:10 ratio was not quite satisfactory to me, probably because of the high viscosity of castor oil or high volume of calendula petals. Anyway I went with a 1:15 ratio.

If your carrier oil doesn't already contain any antioxidant you can the antioxidant at this step. We recommend addition of 0.2-0.5% tocopherol or 0.1% rosemary CO2 extract. This would protect the oil and the extract against oxidation.

I soaked the petals in the oil for a few hours @RT. You can expand this time to 24 hours. Just take care that the container is fulled covered and stored in a dry and moderate temperature place without direct exposure to sun and heat. For some harder plant material such as rhizomes and barks you need to soal your material overnight.

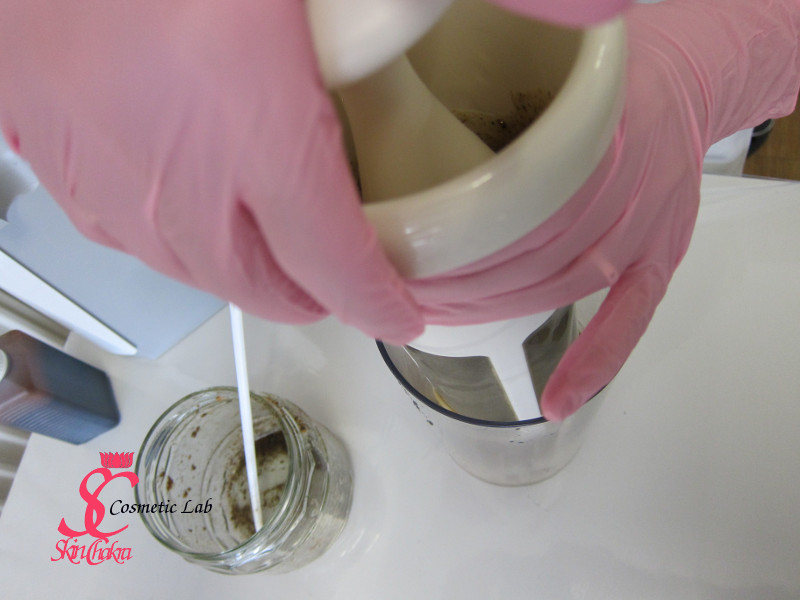

After a few hours we started mechanical agitation with our handy-dandy crusher/turbo mixer. You can use your Blendia for this purpose.

Read our previous post:

How to make herbal extracts with your "Blendia"

You only need a few minutes of pulsing and you can visually observe that the plant material is crushed to a powder like consistency.

It is important to keep the temperature around 15-25 oC. You can hardly imagine how much heat Blendia can cause. If you feel that the vessel (and its content) is becoming warm (specially in summer) use a cold water or ice bath to avoid overheating.

After this step, you can start gently blending the mixture. Here you can use a magnetic stirrer or an overhead mixer. If you have not of them available use a long spatula and occasionally blend this mixture for a couple of hours.

Now the fun part  begins which is the hardest and the most time consuming part.

begins which is the hardest and the most time consuming part.

The first step of filtration is a coarse filtration with the Veggiefino.

Read our previous post about filtering your herbal extracts and infusions:

How to filter your herbal extracts and infusions (part I)

This is one of the most brilliant tools for a hygienic filtration of extracts, macerated oils, infusions and (what it originally is made for) vegan milks.

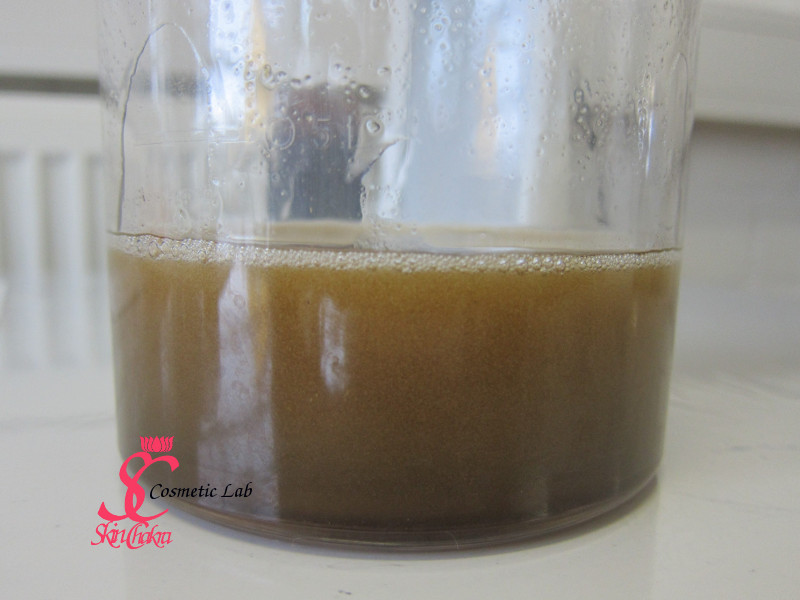

After this step, the extract would look like this

It is yet far from a pretty and nice extract and has suspended particles but contains no big chunks of plant material anymore.

From this step, we ran several further filtrations. You can leave the gravity do the work, cover the extract completely and store it in a cool and dark place and decant it after about 1-2 weeks or you can go through these filtration steps.

How to filter your herbal extracts and infusions (part II)

How to filter your herbal extracts and infusions (Part III)

At the end, you'll have a pretty (more or less) extract like this

As you see, it is not quite yet clear but this degree is quite enough to use the extract in oil blends, balms and lotions without compromising the stability. If you let this extract settle, some very fine particle with sediment over 1-2 months and then you can either decant the extract once more or run another filtration sttep.

We're going to run a centrifuge filtration and share the results with you.

I hope you'll enjoy this tutorial and will enjoy making your own extracts in turn.

Don't hesitate to send us your photos, comments and questions. You can post your photos on our Facebook page or tag us (@skinchakra) on Instagram .

BeHappy and have fun

Ref:

1-Krist, Sabine, Gerhard Buchbauer, and Carina Klausberger. Lexikon der pflanzlichen Fette und Öle. Springer-Verlag, 2009.