Donnerstag, 25. November 2021

Emulsion making 101: oil polarity and texture

The polarity of the lipids can make or break a formulation yet this important subject is seldom covered in all those cosmetic chemistry and formulation courses and diploma of this and master grade of that. Most formulators who have no background in chemistry of chemical engineering are not even aware that there is a difference in oil polarity.

We have covered this topic in detail in our members' only portal but to provide our non-member readers and followers with bits of knowledge, we made a series of experiment to show you the impact of the oil polarity on a given emulsion formulation.

Cleansing oils and the oil polarity

Even if you have no background in chemistry, you certainly are aware that water is a polar solvent and prefers polar molecules. Now lipids are basically insoluble in water but when you make oil-to-milk cleansing oils or bath oils you use an emulsifier to help emulsify the product when you add water to the product. Although these formulations are rather straightforward and non-complicated, the out come of the product and specially the skin feel after rinsing is extremely dependent on the choice of the oils you use. The more polar oils in the formulation, the easier it is rinsed away and the nicer is the skin feel after rinsing.

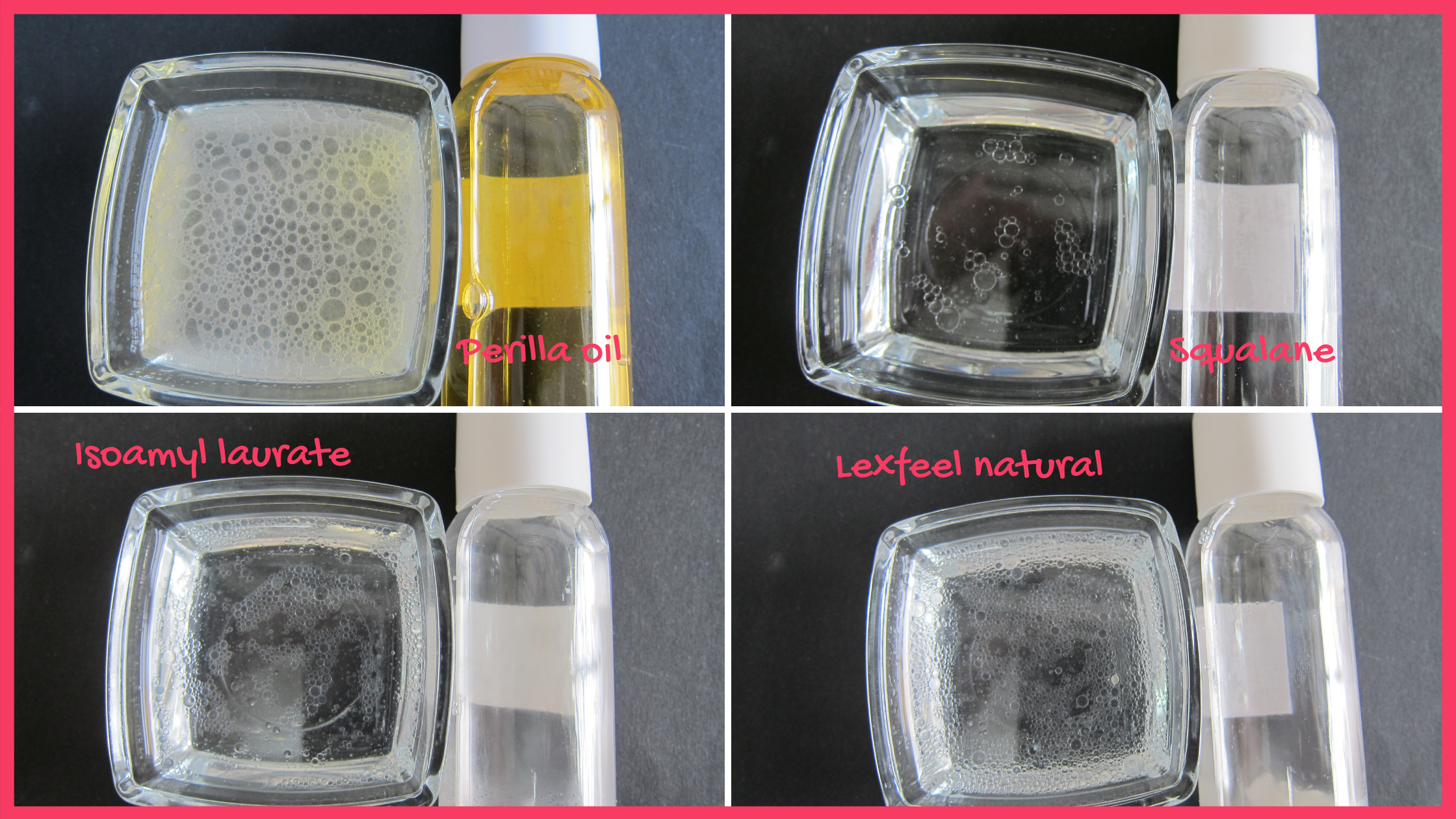

In this photo, we show you how different cleansing oils with varying oil polarity look like and how they perform when water is added to the formulation.

Gel-to-milk formulations

Here the impact of the oil polarity is even higher. Not only the viscosity and the appearance of the formulation changes with polarity, the stability is extremely dependent on the oil polarity and you may turn a stable formulation to a unstable crap by applying tiny changes in the polarity of the oils used in the formulation.

Emulsions and oil polarity

Here again, the changes in the polarity can make or break the formulation. Most emulsifiers work with both polar and not-polar oils but each emulsifier has its own specific preferences. This means that some emulsions work better with more polar oils and some prefer less polar oils. Changing in the polarity of the oils used in an emulsion can have a huge impact on the viscosity (and the stability), the texture, the skin feel and on the required packaging method. You may turn a free-flowing emulsion that is easily applied from a lotion pump to a high viscosity cream that must be filled in a jar or a tube by just swapping 2% of an oil with another oil.

In today's post we share our results from a very basic formulation with the anionic emulsifier GSC palm oil free.

A few weeks ago we shared a video and blog post for a KISS formulation and 4 variations with this emulsifier. For this post, we varied the formulation just a little bit but the basic procedure is exactly the same. We used tigernut oil as the base oil. This is a plant oil with low polarity and a low iodine value and can be used in hot process. We then swapped 5% of the oil with less polar and more polar oils than the usual plant oils. The samples have all passed the stability testing. There is a difference in the viscosity, teh texture and the skin feel. Apart from that, the polar and non-polar oils we used have a higher oxidative and thermal stability compared to the liquid plant oils and swapping the plant oil with these lipids will improve the oxidative stability of the emulsion and prolong its shelf-life.

Formulation

| Phase A | |

| Distilled or deionized water | to 100,0% |

| Aquaxyl | 2,0% |

| Na-Citrate | 0,5% |

| Natural chelator PA-3 | 0,1% |

| Phase B | |

| Solagum AX | 0,3% |

| Tara gum | 0,1% |

| Phase C | |

| Oil* | 20,0% |

| GSC palm oil free | 5,0% |

| Natural tocopherols | 0,3% |

| Phase D | |

| Paprika oil | 1,0% |

| Phase E | |

| Na-lactate | 2,5% |

| D-Panthenol | 0,5% |

| Phase F | |

| No-Kons PA20 | 1,0% |

| Mandarine oil | 1,0% |

| Lactic acid | to adjust the pH |

* Oil composition

1- 20,0% tigernut oil

2- 15,0% tigernut oil + 5,0% isoamyl laurate

3- 15,0% tigernut oil + 5,0% Triheptanoin

4- 15,0% tigernut oil + 5,0% Bergacare olive (natural silicone alternative)

5- 15,0% tigernut oil + 5,0% olive sualane

Procedure:

1- Blend phase A and C in heat proof containers

2- Disperse and hydrate the gum in the water phase @RT

3- Heat phase A+B and C in a water bath between 80-85 C

4- Emulsify the oil phase in the water phase and homogenize for a few minutes

5- Start cooling down while stirring

6- At a temperature < 50 C add the paprika oil and stir a while

7- Add phase E and stir

8- When the emulsion reaches RT add the preservative and the essential oil. Prepare a 10% dilution and measure the pH. It will be around 6,5 with this composition. Add lactic acid to reduce the pH between 4,9-5,2 (the preservative we are using works independent of pH)

Results

As mentioned before, plant oils have a medium polarity. From the among additives the squalane is a completely non-polar hydrocarbon and the triheptanoin is the triglyceride with the highest polarity. The silicone alternative and isoamyl laurate both are more polar than the tigernut oil.

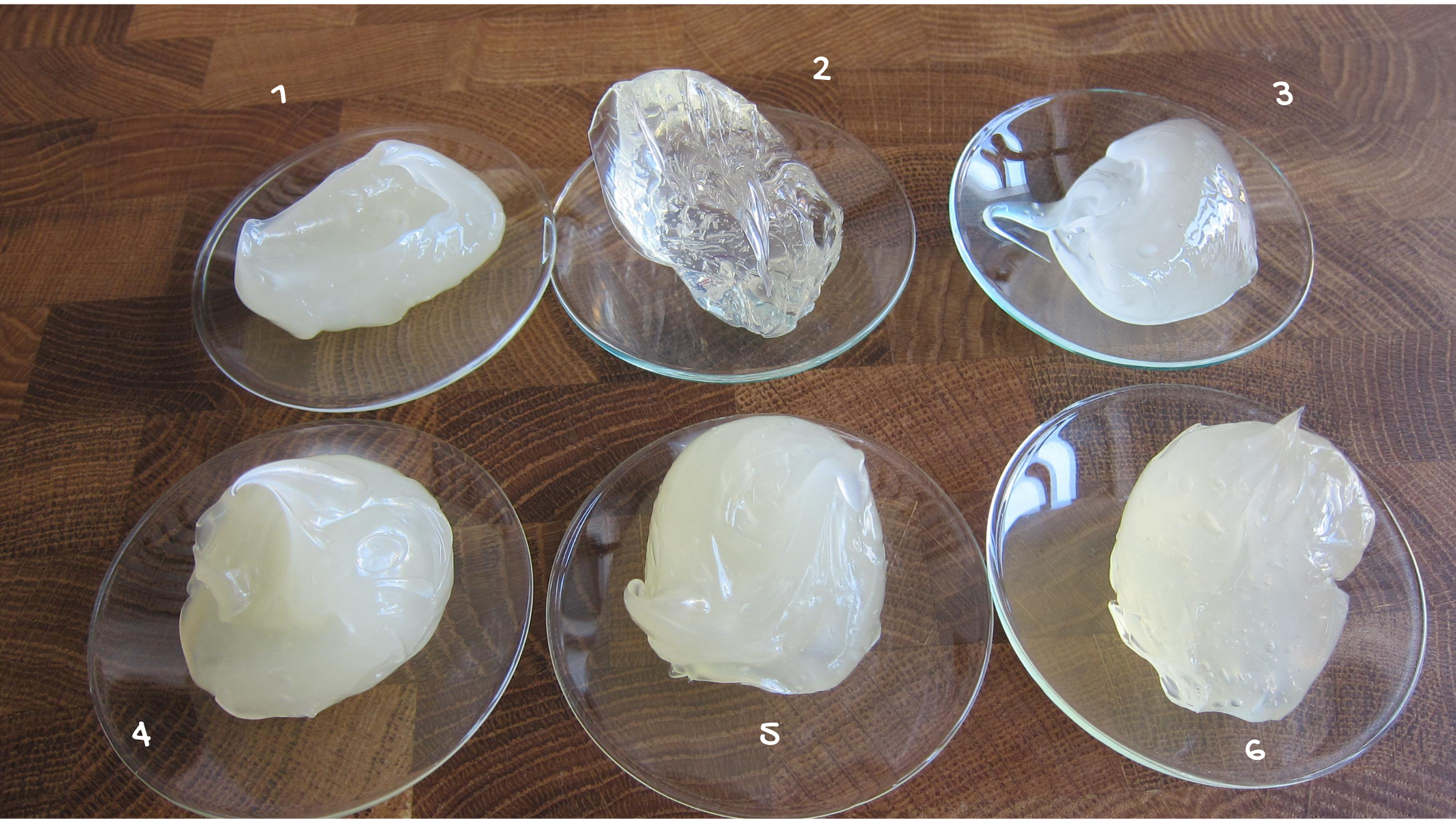

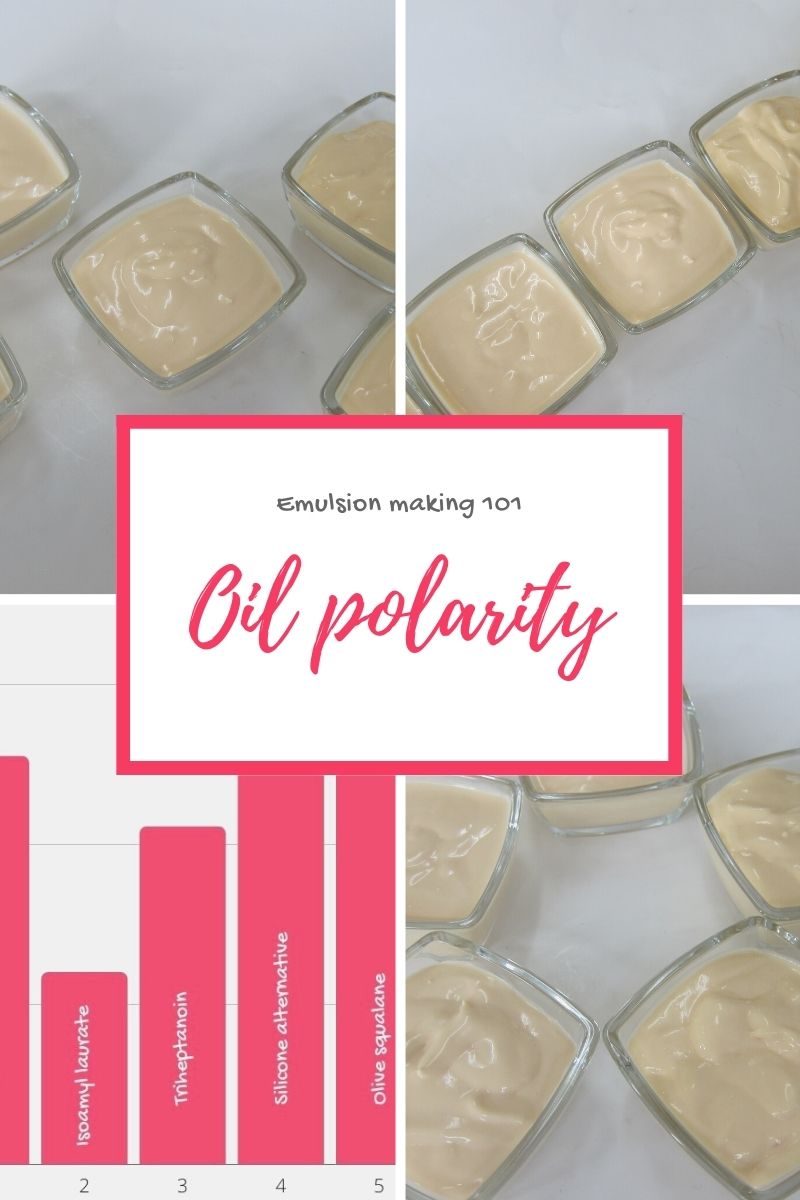

The following picture depicts all samples together. Although the photo does not reveal much about the texture (you can observe the texture in the video), you can distinguish the changes in viscosity between the original formulation and the one made with isoamyl laurate.

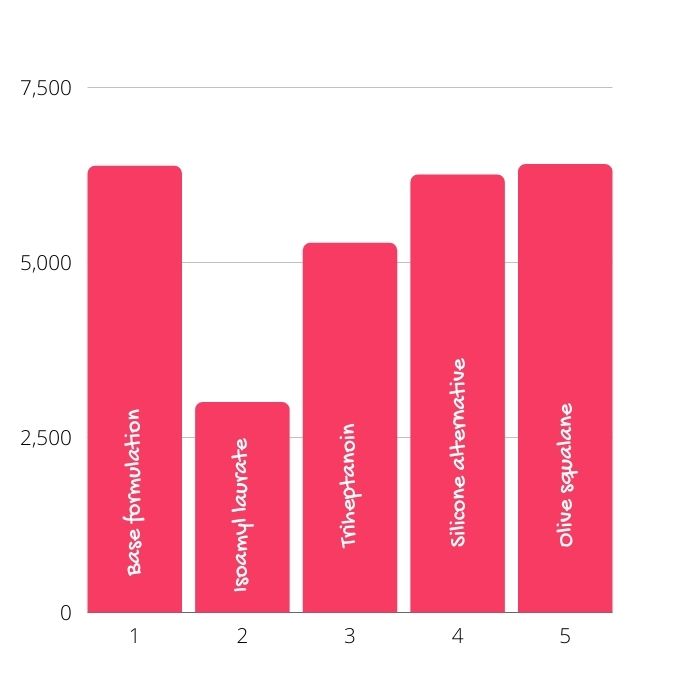

In the viscosity chart you can clearly see that the isoamyl laurate reduces the viscosity almost to a half. Very often you need to compensate the loss in viscosity by adding stabilizers. In this care however the emulsion has an acceptable stability.

Triheptanoin and the silicone alternative both slightly reduce the viscosity and olive squalane slightly increases the viscosity. These changes are really ignorable.

The significant difference is in texture and skin feel. Ester oils basically have a dry emolliency compared to plant oils. They absorb easily into skin and do not feel greasy or tacky. The silicone alternative creates a texture like whipped-butter. Squalane which is the most non-polar ingredient in this experiment imparts a rich skin feel.

You can watch the video demonstration here

Bottom line

By varying the polarity of the oils you are using, you can easily modify the viscosity, stability, texture and skin feel of each emulsion according to your product concept and requirements.