Samstag, 30. Juni 2018

Natural emulsifiers 101

To my own and humble taste emulsifiers belong to the most fascinating cosmetic ingredients. I love testing and playing with emulsifiers, trying to get the hang of it, change several parameters such as oil:water phase ratio, viscosity modifier, mode of application, etc. and then compare the results in a systematic way.

Natural emulsifiers belong to the most progressive and versatile ingredients in "natural" and "organic" personal care. Whereas we need to struggle to find some effective and truly "natural" surfactants (detergents) for a cleansing product, we have hundreds of "natural" emulsifiers waiting to be tested and used by us in emulsions.

Probably most students of hair and skin formulation do not agree with me and struggle with emulsifiers in general and finding a suitable emulsifier for a certain purpose in particular. As a formulator and consultant, I'm very often asked to suggest "the best natural emulsifier". This is something that neither I nor experts with a much more profound knowledge and experience can answer. "The best" doesn't exist as a general term. You may be able to find "the best emulsifier" for a very specific purpose but you can not expand this choice to all other purposes (just like many other ingredients).

The huge variety of "natural" emulsifiers and the inadequate (and sometimes even misleading) information submitted by retailers, does not make the choice easier for students and artisanal manufacturers.

Quite astonishingly, during the last month, I've received several mails from individual students of hair and skin care formulation who were struggling with, if not say the wrong but at least not the best choice of emulsifier for a certain purpose. Some were using a certain emulsifier suitable for low viscosity emulsions and wanted to create a high viscosity cream. Some were using an O/W emulsifier and wanted to create a W/O emulsion and some were (still and despite my many times or repetition) were hoping to use bees wax as an emulsifier.

This made me recap a blog post I have written ages ago about "natural emulsifier" and update that old blog post. Whether you're new to emulsion making or an experienced formulator, you'll find something informative and interesting in this post.

Let's go directly to the core of the matter:

1- an emulsifier is not a solubilizer

This might sound quite logic to you but you can not imagine how many inquiries I receive per month where people are interchanging these two classes of ingredients. Both emulsifiers and solubilizers belong to the large category of "surfactants" (read our previous blog post about surfactants here) and act almost under the same principle, they are completely different ingredients with different applications and they could not be exchanged and interchanged.

I wrote this blog post a long time ago and I'm not going to repeat it here. Please read it for detailed information why we can not interchange a solubilizer and an emulsifier.

2- bees wax is not an emulsifier

Before we proceed further, let me clear this point and exclude bees wax from our discussion. I know there are hundreds (and probably thousands) of DIYers and herbalists who will disagree with me and claim they are creating wonderful emulsions since years and perhaps decades but this doesn't change the fact that bees wax is not an emulsifier. It is a lipid (wax) which should be emulsified itself into an emulsion. What these DIYers and herbalists prepare and have prepared is a cold cream, which might be quite effective and wonderful for their purposes but it is by no means an emulsion and would fail every test we perform to recognise an emulsion.

Since I'm not going to repeat myself and re-invent the wheel, I refer you to this blog post I wrote ages ago for a detailed discussion.

3- Define your own shade of "natural"

There are many shades of "natural" and the sooner you define your shade and policy the better. Look at this blog post more more details.

If you belong to those "purists" who reject "anything" that was processed and created in the lab then I'm afraid you would be left alone with lecithin and probably stearic acid soap as the only available emulsifiers (although soap itself is a product of a chemical reaction between lipids and lye.)

Almost all other "natural" emulsifiers, even those certified by organizations such as Ecocert, NaTrue, USDA etc. are somehow processed. They are "from natural" origin and no petrochemicals are used in the process, still they are produced by several "chemical" reactions.

4- Define your niche

Among the many shades of "natural" you may have other specific requirements for your product policy and ethos. Although specifying a niche would be excellent to distinguish your business and products from thousands of competitors, the more selective you become the less versatile becomes your choice and the number of emulsifiers that might match your demands. To explain what I mean, I'm only mentioning just a few examples:

a- Vegan or not vegan (there are still many emulsifiers available based on tallow or on milk protein which you need to avoid if you've vegan products)

b- Palm oil free (oh dear, this becomes very difficult). Most of the emulsifiers or one of the components in the emulsifier blend (cetyl or stearyl alcohol for instance) are palm derived. If you follow a palm-oil free policy, the choice of the emulsifier would become very challenging.

c- Gluten free: this is another niche which can distinguish your business and product line, yet you need to have this in mind when choosing your emulsifier.

5- Certified or not certified: Depending on your philosophy and marketing strategies as well a legal requirements, you may need to follow certain certifications: Ecocert, Natrue, Halal or Kosher for instance. This means you need to make sure the emulsifier you are going to use is either certified or is accepted by these certifications.

6- Legislatory part: If you're going to sell your products in a certain region of the world, make sure about the acceptance of your emulsifier in that region and the possible limitations to its dosage. Usually, the product brochure will inform you about the global acceptance of the product as well as possible limitations to its application.

7- W/O vs. O/W

Dear me. It seems that there is a public misunderstanding among some DIYers that when you add the water phase to the oil phase you'll create a W/O (water in oil) emulsion and when you add the oil to the water phase you'll create an O/W (oil in water) emulsion no matter which emulsifier you use. I honestly do not know the origin of this myth, but may god bless the blogger who has first published this nonsense.

The nature of the emulsion is defined by the emulsifier. You can not reverse an emulsion by reversing the order of blending the oil and water phase

If you plan to make a W/O emulsion then you need to use a W/O emulsifier and if you plan to make an O/W emulsion then you need to use an O/W emulsifier.

By changing the order of blending the oil and water phase, you usually only cause an emulsion separation rather than creating a W/O emulsion from an O/W emulsifier or vice versa.

The nature of the emulsifier (O/W or W/O) is mentioned on the product data sheet and brochures. In some cases, O/W emulsifiers could be added to W/O emulsifiers as a co-emulsifier and vice-versa but this is not a general rule.

HLB is an old classification system that does not have much sense and application today. For most natural emulsifiers, the HLB value is not even mentioned on the data sheet but in case your supplier mentions a HLB range, the HLB for W/O emulsifiers should be around 4 and the HLB for O/W emulsifiers should be around 12.

Read more about HLB here and here.

8- Cold vs. hot process

The traditional way of using emulsifiers (which is still valid for about 90% of the emulsifiers on the market) is the hot process. This means that you heat the oil and water phase to a certain temperature (which depends on the emulsifier as well as the melting point of the solid ingredients such as waxes in your formulation) and then blend the oil and water phase in the order defined by the emulsifier, emulsify the blend and start cooling the mixture while continuing stirring till the mixture is cooled down. At this stage and at temperatures lower than 30 oC, sensitive ingredients are added and the mixture is further cooled down to room temperature.

This was, and still is quite practical in making conventional cosmetics with paraffins and silicones in the oil phase with a good thermal and oxidative stability.

When making "natural" cosmetics however, we usually work with plant oils, hydrosols and plant extracts which are much more sensitive compared to paraffins and silicone oils. Another aspect in hot vs. cold process is the environmental aspects and the energy consumption that we use during heating and cooling phases. This might be negligible when making a 100 gr batch but becomes quite a considerable factor when making tons of an emulsion in each batch. There are a few "cold process" emulsifiers which work at low temperature and these are perfect when you're working with sensitive oils and other botanical ingredients. Apart from that, there are other emulsifiers which allow you to use a hot-hot-cold process. This means that you can prepare a pre-emulsion by heating some of your ingredients and then add the rest of the ingredients at lower temperatures.

Keep in mind that every cold process emulsion could be used in a hot process as well but hot process emulsifiers could not be used in a cold process.

9- Viscosity range

Usually, you can manipulate the viscosity of an emulsion by:

a- changing the inner phase: outer phase ratio

b- adding viscosity modifiers

c- Varying the emulsifier:oil ratio

However, this manipulation and the viscosity range remain limited in a certain range.

There are certain emulsifiers which create a sprayable emulsion (a very low viscosity so that you can spray the emulsion) and there are emulsifiers that create high viscosity creams suitable only for a cream jar.

Usually you can not create a stable sprayable emulsion from an emulsifier that is suitable for high viscosity formulations and vice versa.

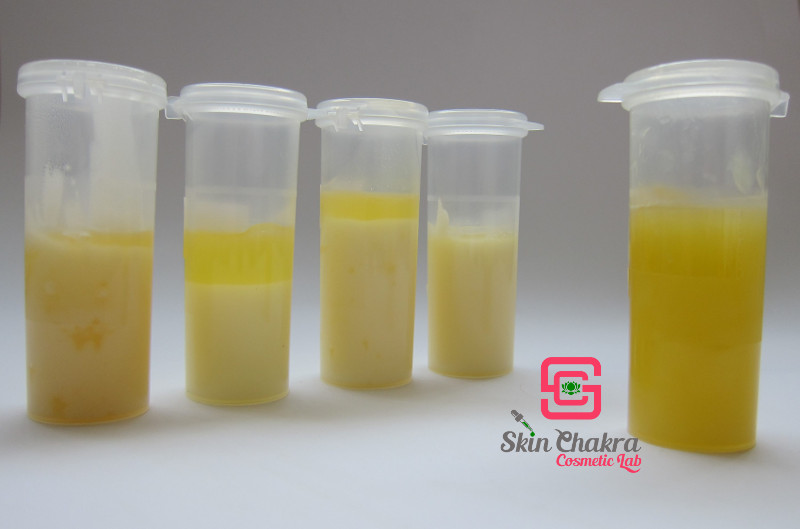

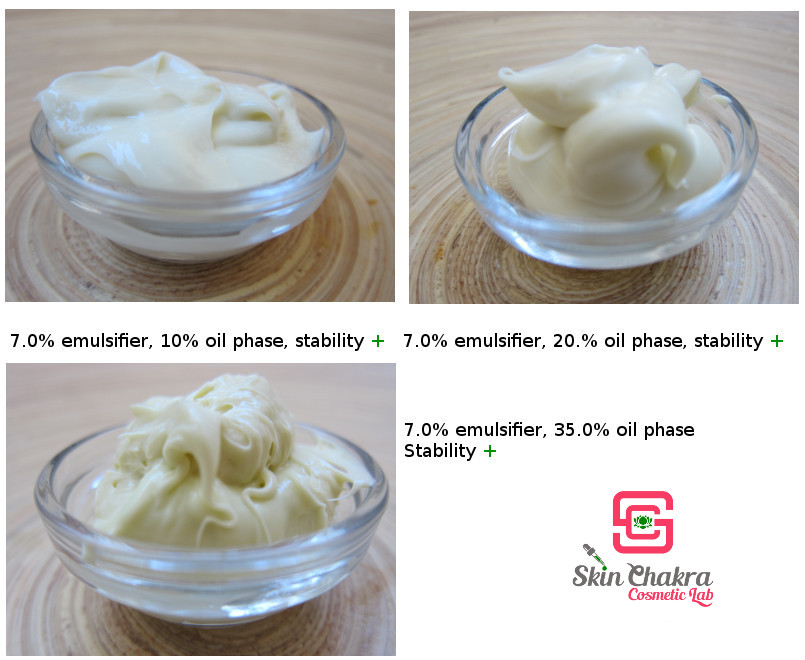

10- Oil phase ratio

Depending on how much oil you want to have in an emulsion, you may find that a certain emulsifier would work better than the others. Each emulsifier has an optimum range of oil phase. Some emulsifiers work better in a low to medium oil phase (5-15%) some work better in a medium oil phase range (15-25%) and a few work better in a high oil phase range (25-45%). This is something you need to consider before you go shopping for an emulsifier

11- Oil phase character

Oil is not equal oil when it comes to emulsifier choice. Some emulsifiers work better with ester oils, some work better with triglycerides (plant oils) and some work better with paraffin and silicone oils (the last two are not allowed in natural and organic cosmetics). Depending on which oils you're using (liquid oils, butters, waxes or ester oils) you may need to prefer one emulsifier over another one.

12- pH range

For the majority of hair and skin care products, the pH is between 4,5-6,0 and this is in range of most of the emulsifiers. If you're making products that are out of this range (chemical peeling, deodorant, hair removal or hair waving for instance), the pH of the product is much lower or much higher than this range and you need an emulsifier which works in this range

13- ionic character

Most emulsifiers have a neutral character (nonionic). Some emulsifiers have an anionic character (such as sodum lauroyl lactylate) or one anionic component and in very rare cases, some emulsifiers have a cationic character. Nonionic emulsifiers have a good compatibility with ionic ingredients but when you use an anionic or a cationic emulsifier you need to consider the compatibility of the emulsifier with other anionic ingredients. (You can not use an anionic emulsifier with a cationic gum for example). Read more about the surfactant types and ionic character here.

14- Compatibility with other ingredients

Make sure that your emulsifier is compatible with all other ingredients in your formulation. Some ingredients cause a reduction in viscosity and that must be compensated with a stabilizer otherwise the stability is compromised. Some may cause a colour change or even breaking of the emulsion. Alcohol (ethanol in tinctures and absolutes), oxidizing agents and electrolytes are specially tricky ingredients and if you're going to use any of them (deodorant, hair colorants, hair removal etc.) you need to make sure your emulsifier is compatible with these ingredients.

15- Inherent colour and scent

Some emulsifiers have a significant inherent colour or scent that can over power your final product. If you're going to prepare a snow white emulsion for instance, you need to avoid emulsifiers with a strong yellowish colour.

16- need for a stabilizer or co-emulsifier

We usually use a gum to improve the stability of an O/W emulsion. Some emulsifiers need special stabilizing or buffering ingredients in certain circumstances or as a general requirement. Some need a co-emulsifier such as a fatty alcohol or a fatty ester. These factors should be considered in formulation and in your price calculations.

17- Shear tolerance

This is a technical point for manufacturing procedure. Most emuslifiers have a good shear tolerance. This means you can use a turbo mixer or homogenizer at high speed to create a stable emulsion. In very rare cases, the emulsifier doesn't like high shear and this means that by using a high speed homogenizer or turbo mixer, you'll destabilize the emulsion. Have a look at this short video in which we briefly demonstrate the difference between a homogenizer and a stirrer.

18- Application dosage

Application dosage is an important factor when it comes to pricing and budget. Some emulsifiers have a low dosage but need an additional co-emulsifier or stabilizer. Some emulsifier blends already contain a co-emulsifier or stabilizer but they have a high dosage. You shall consider all these factors when you're making a decision about an emulsifier

19- Price, MOQ and availability

Before you fall in love with a certain emulsifier, consider its price, the minimum order quantity and its availability. Although at SkinChakra we ship to more than 50 countries in the world, we recommend our customers to try to source their ingredients from regional suppliers (alone for the sake of less transport costs and CO2 production). Consider that, specially with plant based emulsifiers, the prices might be variable according to changes in the starting material. No matter how much you love nature and how much you love a certain ingredient, your business is no business if you don't make any profits.

20- Texture and skin feel

There is no "one-fits-all" emulsifier. You may love the texture and skin feel of an emulsifier for a foot cream or a body lotion, but that emulsifier might not be quite as pleasant in an undery-eye serum.

Keep in mind that most "natural" emulsifiers have a kind of soapiness when applied over skin (Olivem 1000 is the most aweful one of all emulsifiers when it comes to soapiness). You may need to blend some emulsifiers to improve the stability, enhance the texture and reduce soapiness.

Has anybody ever claimed it's easy to formulate skincare?

21- Ready for painful experiences?

This is probably the most difficult part of decision making and is something you even don't have any control over. I just want to prepare you for the real life as a formulator /business owner. Unless you're making coldcreams with bees wax or confine yourself to making emulsions with saponified stearic acid, all modern emulsifiers are patented proprietary blends. This means, you may find 50 retailers for a certain emulsifier but there would be only ONE manufacturer for that emulsifier and your whole business (or at least the life and destiny of the product you're making with that certain emulsifier) would depend on ONE single manufacturer and its business policy. This is not confined to emulsifiers, every other proprietary blend (specialty active ingredients, preservatives etc.) have the same destiny.

I'm not going to scare you or extinguish the desire and curiosity to formulate and test new ingredients in you. I'm just trying to prepare you for the reality.

Let me give you some examples of my own experience:

Xyliance, which is a specialty emulsifier and one of the very first "natural" emulsifiers on the market is a very nice ingredient and I have spent hundreds of hours to test it, create different formulations and write tutorials. This emulsifier was first produced as a palm-oil free ingredient and it was an additional attractive aspect of it. Then Soliance (the original manufacturer) was swallowed by Givaudan and they decided to make more profit by sourcing the raw material for this emulsifier from palm-oil. This means all those manufacturers who have worked and made business with this emulsifier as a "palm-oil-free" ingredient had to either change their ethos and policy or change their formulation (with all the regulatory drama associating a formulation change).

We have decided not to restock this emulsifier anymore because of the unpredictable price and policy changes tried by Givaudan.

Another (painful) example is one of my own personal favourites, Dermofeel G5O from Dr. Straetmans. Those of you who follow this blog are aware of tens of tutorials I have published about this amazing ingredient. It was not only one of our best sellers, it was an ingredient that many of our small business customers have made a product with it: making and testing formulations, challenge and stability testing, safety assessment, creating and uploading the PIF (for customers in the EU), packaging and label design, etc. etc. There was nobody who had tested this ingredient and didn't love it. I even used it in a hair care product I formulated for a hair care course. Then, out of the blue, the manufacturer decided to stop manufacturing this ingredient because of regulatory affairs and because it didn't bring the profit they had expected.

Have the above points in mind when you search for a new emulsifier. Communicating with your supplier and specifying your demands with narrow the choice and spare you time and unnecessary testing.

Wish you good luck

BeHappy and have fun