Sonntag, 3. September 2017

Back to school jelly soap

It's back to school time and we've prepared a fun project for you that motivates even the grumpiest kid to pack his school bag and become ready for the school begin (in Bavaria, we start on 12th of September).

This is quite an easy and fun project and you can even do it with kids. We're not doing any saponification and not using any lye (which we strictly recommend not to use with kids).

The trickiest part is to choose a correct blend of gums and to disperse the gum in the water phase. There are other variations of this soap that are made with gelatin but we wanted to create a fully natural and vegan soap for you.

For this project, we've used a blend of Solagum AX and Konjac gum. None of these gums creates a gel on its own (they create high viscosity solutions but not a real formable gel) but in combination, they create a gel that you can easily pour into a mold and demold as a standalone form.

Read our previous blog post about the combination of Xanthan and Konjac gum here:

Xanthan meets konjac

We made our formulation pretty simple and straightforward and we recommend that you make your first formulations simple as well. After you're satisfied with the consistency and performance, you can expand the formulation and add your personal notes of additives to it.

This is a surfactant based formulation meaning that there is no soap and saponification involved. You can adjust the pH (according to the performance of your preservative) in the skin-friendly region between 5-5,5 (in contrast to the soap). Since the formulation is water based and the pH is in neutral range, guess what? You'll need a preservative. We've decided to use Euxyl K903 which is a broad spectrum and effective preservative blend.

About Euxyl K903:

Please note that Euxyl K903 contains benzyl alcohol which is a known fragrance allergen. Some people with compromised skin react to this preservative (although it is approved for use in natural and organic formulations). If you belong to those people, feel free to swap the preservative with any other suitable blend of your choice but just make sure you test the efficacy of the preservative and that you adjust the pH of your product in the efficacy range of your preservative.

Read our previous posts about the importance of adjusting pH in the cosmetic lab:

pH measurement in cosmetic lab: why we dilute samples?

How to adjust the pH of your cosmetic products

How to use a portable pH-meter (Guest post)

What you need to know about pH measurement

How to protect your "natural" preservatives from deactivation

About other ingredients and procedure:

Since we're going to heat the gum phase for a while we didn't use any fanciful hydrosols and just used plain distilled water (freshly boiled). You can swap the water with a herbal infusion or use a hydrosol if you want but be aware that you'll heat the water phase for a while (about 10 minutes for 100-500 gr batches).

Consider the dermal limits of the essential oils you're going to use and specially take care of the recommendations and restrictions if you prepare this jelly soap for small children.

We disperse the gum in water at room temperature but you may want to disperse the gum in hot water for an easier dispersion (specially if you're not working with an efficient overhead mixer). The surfactant phase is blended separately at room temperature. If you have a magnetic stirrer, it is perfect for this purpose, if you don't have any, that's fine and you can blend your surfactants with a spatula (for small batches). Just make sure that you do not agitate the surfactants too vigorously, you don't want to create foam at this step.

Formulation:

| Phase A | |

| Freshly boiled distilled water | to 100,0% |

| Solagum AX | 0,8% |

| Konjac | 0,8% |

| Phase B | |

| Organic and palm-free glycerine | 5,0% |

| Organic pentylene glycol | 5,0% |

| Decyl glucoside | 5,0% |

| Cocamidopropyl betaine | 5,0% |

| Yucca extract | 1,0% |

| Panthenol 75% | 0,5% |

| Dermofeel PA-3 | 0,1% |

| Euxyl K903 | 1,0% |

| Phase C | |

| Organic sweet orange essential oil | 0,7% |

| Organic petitgrain essential oil | 0,3% |

| Lactic acid (if necessary) | a few drops |

Procedure:

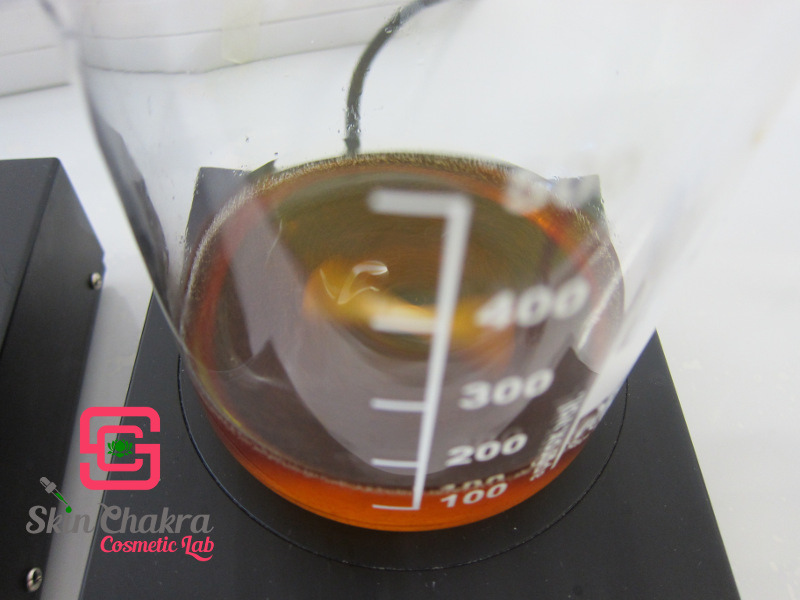

1- Disperse the gum blend in water. As you see, we're dispersing the gum directly in water without predispersing it in glycerine. We're using an overhead mixer with propeller blades and it can easily manage the direct dispersion of gum. If you are using a spatula or other tools, you may predisperse the gum in glycerine+ Pentylene glycol and then add this blend to the water. This helps a better dispersion and reduces the clumps. You may even want to heat the water phase and then disperse the gum

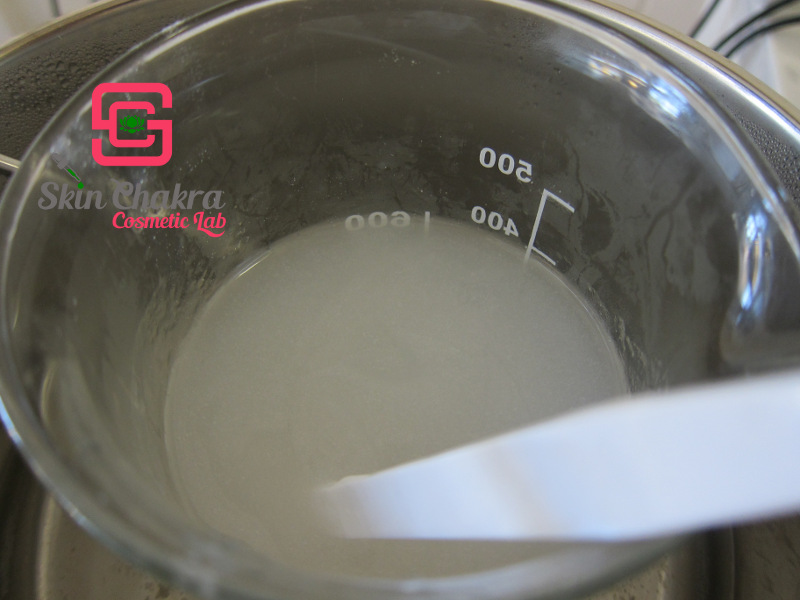

2- Blend phase B (surfactant phase) in another beaker at room temperature.

3- After both phases are uniform, start heating phase A @ 70-80 oC in a water bath. You just need about 10 minutes for small batches. Stir the content during heating.

4- Remove the beaker from water bath. Stir it for a few minutes and slowly add the surfactant phase. Try to avoid agitation and excessive foam building. Formation of a little bit foam is however inevitable.

5- Here you need to act fast. Prepare a 10% dilution of the product and measure the pH. In our case, it was between 5-5,5 and (lucky us) we didn't need to adjust the pH. If you are using other surfactants you may need to add some lactic acid to reduce the pH to the range of your preservative efficacy. For the first couple of times you may feel a little bit clumsy and wish you were an octapus but for your next batches you will have an estimation of the pH and how much acid you may need to adjust the pH.

6- Heat the blend for a few minutes again in the water bath (I know we already have the preservative in there but that is OK, just 2-3 minutes).

7- Remove the blend from the bath. Blend it gently till the temperature arrives around 50-55 and add the essential oils.

8- You can use almost every possible molds for this project. We've used silicone molds.

9- Pour the soap into your mold vacities and tap the mold a few times against the counter to reduce bubbles.

Put the molds into the fridge at least for 15 hours (we put them overnight). Patience and waiting is probably the hardest part of the project.

10- Take the soap out of the mold and enjoy and share its beauty

About packaging:

Please consider that this soap is not comparable with either saponified soap based on plant oils or the M&P soap. It has literally a jelly like consistency and you can not use a heat gun to shrink the wrap around it (like we do in case of M&P soap). You can wrap the soap in wax paper and then in a cardboard box or put it in a metal box. Depending on the temperature of the region you're using (or shipping) this soap, you may need to increase the concentration of the gum to make it a little bit more stable and harder. Play with the ingredients to come to the desired consistency.

If you're inspired by this tutorial feel free to send us your photos and comment either per mail or to our Facebook page. If you post any photos on Instagram, don't forget to tag @SkinChakra.

BeHappy and have fun